- Member Login

Air Brake Chamber Pushrod Stroke

To be able to stop effectively in every braking situation, all components in the air brake system, including the foundation brakes, must be properly installed and maintained by qualified technicians. Air brake chamber (or actuator) pushrod stroke must be kept within the regulation limits (or readjustment limits if in reference to manual brake adjusters, which are permitted only on older vehicles) specified by U.S. and Canadian regulations.

During day-to-day driving a driver cannot “feel” how well brakes will work during an extreme braking maneuver. The most effective check of air (drum) foundation brakes is to measure the pushrod stroke to confirm it is within federal specifications. If pushrod stroke is beyond the regulation limit, the foundation brake may no longer be capable of providing full braking force, and the brake needs servicing.

Failure to properly service brake systems is the most common reason drivers (and motor carriers) are issued vehicle out-of-service (OOS) orders. When pushrod stroke exceeds the regulation limit, something is wrong with the brake and it is a violation.

The brake chamber pushrod regulation stroke limits were established to ensure there is sufficient pushrod travel to apply full force to the foundation brake under all operating conditions. The limits are based on the size of the brake chamber and whether the chamber is a standard or long stroke design. Pushrod stroke in excess of the regulation limit not only violates federal regulations but, more importantly, begins a decline in the force – eventually to zero – at the foundation brake, which will increase the distance it takes to stop the vehicle or combination. The only way to tell when you have a pushrod stroke violation is to measure the stroke while applying the service brakes at sufficient pressure.

Most heavy vehicles on the road are equipped with self-adjusting (automatic) brake adjusters (S-ABAs). Trucks and buses manufactured in the United States after Oct. 20, 1994, and in Canada after May 31, 1996, equipped with air brakes must automatically adjust for normal wear in the brake system, thereby helping to maintain proper pushrod stroke. The use of SABAs has helped significantly reduce the rate of out-of-service brake violations.

However, even with properly working S-ABAs installed, abnormal or excessive wear or broken components can result in excessive pushrod stroke, so stroke should still be measured on a regular basis. If a vehicle has manual brake adjusters (allowed on vehicles manufactured prior to the dates above) it must be measured regularly and adjusted accordingly.

By following manufacturer recommended foundation brake maintenance intervals (for lubrication, lining replacement, wear tolerances, etc.), regularly measuring the pushrod stroke, and addressing issues as they arise, crash risk can be reduced, a company’s safety rating can improve, and the chances of a violation or OOS condition are greatly reduced.

For more information, download the “Air Brake Pushrod Stroke: Why Is It So Important?” brochure.

Air Brake Adjustment

Air brake adjustment and in-service check.

Air Brake adjustment (push rod travel) must be checked as part of the pre–trip air brake inspection (Section 9).

On vehicles equipped with hydraulic brakes it is possible to pump the brake pedal to compensate for brakes that are out of adjustment. This is not possible with a vehicle equipped with an air brake system with manual slack adjusters. When the brakes are adjusted by slack adjusters, the shoes are moved toward the drum. This brings them as close to the drums as possible minimizing the amount of free travel when the brakes are applied. It also reduces the volume of air used to apply the brakes.

Your company may have a maintenance crew to keep vehicles safely running. But one person alone is ultimately responsible to ensure that the brakes are operating properly before the vehicle is moved. That person is the driver.

Brake Adjustment – It’s Critical

The most important part of any braking system is the foundation brakes. If these are not in correct working order and properly adjusted, the best designed air brake system won’t be able to safely stop the vehicle.

Unfortunately, brake adjustment is often neglected. The reality is that brake failures and runaways that result in crashes are almost never caused by an air system failure, but by the absence of routine brake maintenance, or by the driver failing to check brakes on a daily basis.

Daily pre–and post–trip inspections are mandatory. The driver may be held responsible if the brakes are incorrectly adjusted or not working properly.

Brake Adjustment – It’s the Law

Federal and provincial laws require that manual and automatic slack adjusters be checked daily, during the pre–trip inspection. It is up to you, the professional driver, to ensure your vehicle has safe, correctly adjusted brakes. You the driver, can be fined if the brakes on the vehicle you are driving are found to be out of adjustment.

You’re also required by law to check your brakes before driving down steep grades that are posted with regulatory signs.

You can’t always crawl underneath your vehicle to measure air brake chamber pushrod travel, but there are devices available to help you visually check for brake adjustment.

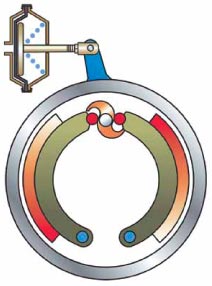

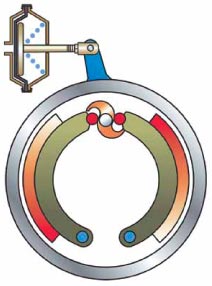

S–Cam Brake–Release

S-cam brake–applied.

The most common type of air brake chamber used on trucks and trailers is the Type 30. These chambers have a maximum available stroke of 2M inches. A long stroke Type 30 is designated Type 30LS, and has a maximum available stroke of three inches.

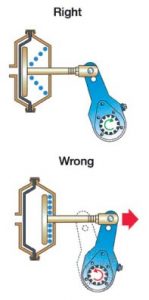

In this diagram, the brakes have been applied and the brake linings have contacted the brake drum. The brake chamber has stroked less than M of its maximum stroke, indicating that the brake is in correct adjustment.

Each brake on an axle should be adjusted to have a similar amount of pushrod travel—that is, the pushrod travel of the left brake should be similar to the pushrod travel of the right brake on the axle.

Checking and Adjusting S–Cam Brakes–Manual Slack Adjusters

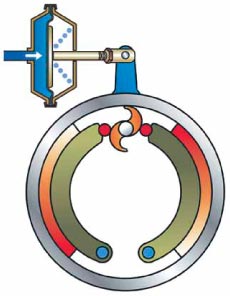

S–cam brake–incorrectly adjusted and hot brake drum.

This brake chamber pushrod has excessive travel, but may work as long as the brake drum is cool. But it won’t stay cool for long!

Note that the brake chamber has stroked more than ½ of its maximum, which means that this air brake chamber pushrod has excessive travel and the brakes are in need of adjustment.

When the brake drum is cool and with normal brake application pressure, the brake will seem to be effective, so it is easy to be lulled into a false sense of security.

Air brake equipped vehicles rarely “lose” their brakes. Rather, brake failure occurs because the driver has failed to check and correctly adjust the brakes.

Cast iron brake drums expand when heated, causing the air chamber to stroke further and further as the temperature rises.

If an unforeseen event required the driver to make a sudden stop, the brake chamber could bottom out, and braking power would be greatly reduced.

On long downgrades, the expansion of hot brake drums can cause a total loss of braking and result in a runaway.

Even incorrectly adjusted brakes may seem to work when brakes are lightly applied.

This could result in brake fade under moderate to heavy braking, or on a downhill.

S–Cam Brake–Incorrectly Adjusted and Cold Brake Drum

Drivers seldom have the luxury of having the use of a pit and hydraulic jacks so that brake adjustment can be done with wheels off the ground. However, brakes can still be adjusted very accurately with the wheels on the ground using one of the following methods. Be sure that the vehicle is safely parked with the wheels blocked. The air system should be at full pressure and the spring parking brakes released. Turn the engine off so that you can listen for air leaks. There are two methods of checking for correct adjustment, but the measurements that indicate the need for adjustment are different. Pry Method of Free Stroke Measurement

You will need:

- A marker to measure pushrod travel

- Sturdy clothing suitable for crawling under the vehicle

- A flashlight

You should also wear eye protection and a bump cap. To begin, make sure system air pressure is at least 90–100 psi and all parking brakes are released.

- Make a mark on the pushrod where it exits the brake chamber.

- Note: It is sometimes difficult to mark the pushrod at this location. Alternatively, mark the center of the clevis pin on the slack adjuster arm.

- Pull the pushrod out from the brake chamber, using a tool for leverage.

- Measure the distance between the chalk mark and the face of the brake chamber ½ to ¾ of an inch of free stroke is a good range for a type 30 standard stroke brake chamber. If this distance is more than ¾ of an inch, the brakes need adjustment.

Applied Stroke Method (service brake application)

The applied stroke (brake application) method requires two people—one to apply the brakes and one to measure travel.

If you have a device to apply and hold the service brakes on, you can use the brake application method without needing another person.

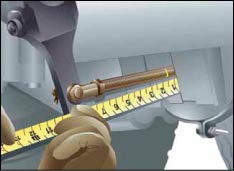

Checking the pushrod stroke by applying the brakes.

Brake Adjustment Indicators

New air brake chamber pushrods have a marking (usually red) to indicate when brake adjustment must be done immediately. If the pushrod travel becomes excessive, the marking will show.

Don’t wait until the red marking is exposed before adjusting the brakes.

If the red marking on the pushrod (at the chamber face) is visible, it indicates that the brake is dangerously out of adjustment and it needs immediate attention.

The applied stroke method is the preferred method and is also a method recommended by commercial fleet maintenance supervisors.

- With the brakes released, make a mark where the pushrod exits the brake chamber.

- With the engine off, make a series of brake applications to reduce the reservoir pressure to between 90 to 100 psi.

- Apply and hold a full brake application (90 to 100 psi).

- Measure the distance between the mark and the face of the brake chamber. The difference between measurements is called the chamber applied stroke.

While checking air brakes look for other brake component wear and excessive play including:

- S–cam bushing wear

- S–cam spline wear

- Slack adjuster play (worn gear)

- Clevis pin wear

Brake Adjustment–Manual Slack Adjuster

With a typical Type 30 standard stroke brake chamber, you must adjust the brakes if pushrod travel is:

- more than ¾ of an inch using the pry method of free stroke measurement, or

- more than 1-½ inches using the brake application—applied stroke measurement method.

Note that these are maximum measurements. You should adjust the brakes if your measurements approach these limits.

Most manual slack adjusters have a spring–loaded locking sleeve that must be pressed in and held so the adjusting bolt can be turned.

Depending upon the orientation of the slack adjuster, the correct direction to turn the adjusting bolt may be clockwise or counterclockwise. Watch to ensure that you are tightening and not loosening the slack adjustment.

With a wrench of the proper size, usually a 9/!^ inch, depress the locking sleeve and turn the adjusting bolt while watching the end of the camshaft. The camshaft will rotate slightly as the bolt is being turned. If you are turning in the right direction, the cam will rotate in the same direction that it would if the brakes were being applied, as shown by the arrow on the cam end in the diagram below.

The push rod and the slack adjuster arm should never move away from the brake chamber while turning the adjusting bolt.

If when turning the adjusting bolt, the slack adjuster is pulling the pushrod out of the chamber, stop. The adjusting bolt is being turned in the wrong direction.

Once the proper direction is established, continue turning until solid resistance is met. This indicates that the brake linings have contacted the brake drum.

If the brake has no dust shields, or if you can see the brake shoes and linings through an inspection slot, you can visually verify that the linings have contacted the drum.

Backing off the adjusting bolt about 1 ⁄ 3 of a turn should establish correct running clearance between the lining and drum. Be sure the locking sleeve re–engages the bolt so that the adjustment will not back off.

It is common, especially on tandem axle units, for the adjusting bolts on one axle to adjust in one direction, while the other axle requires an opposite turn. It is not uncommon to find that the brakes on one or the other axle have been mistakenly backed off, creating a serious safety hazard.

After adjusting, verify that there is sufficient clearance by again pulling or prying on the slack adjuster arm, and re–measuring the free stroke, remember that ½ inch is ideal.

Adjusting S–Cam Brakes with Automatic Slack Adjusters—Why—When—How

Automatic slack adjusters are entirely different than the manual types.

Once properly installed, automatic slack adjusters should not need manual adjustment. If an automatic slack adjuster is found to stroke beyond the maximum allowed, this usually indicates that there are brake problems that need to be repaired by qualified brake service personnel.

Automatic slack adjusters still need to be regularly checked to ensure that correct adjustment is being maintained.

Pushrod strokes with automatic slack adjusters are usually slightly longer than with well–adjusted manual slack adjusters. While a manual adjustment may temporarily shorten the stroke, the automatic slack will soon re–set to its designed stroke.

Manufacturers recommend that automatic slack adjusters be checked by a mechanic at each chassis lubrication interval, or from 40,000 to 80,000 km.

However, the National Safety Code of Canada, as well as federal and state laws in the U.S. require a daily check of brake adjustment as part of a pre-trip inspection. Also, in certain mountainous areas of North America, trucks are required to stop and check brakes before proceeding down long grades. The checking is required regardless of whether manual or automatic slack adjusters are used.

Prior to manually checking slack adjuster stroke, ensure tractor spring parking brake control valve and trailer supply valve are open. Ensure reservoir air pressure is above 90 psi and make a full brake application and release. Repeat this process 6 times—these brake applications will be adequate to cause an automatic slack adjuster to adjust. A light brake application will not cause the adjustment.

If after making 6 full brake applications with reservoir pressure above 90 psi, a pushrod stroke is excessive, the automatic slack adjuster has either failed, been incorrectly installed, or there is a problem within the foundation brake. Manual adjustment at this time is only a stop–gap measure so the vehicle can be driven to a service depot for inspection and possible replacement.

Most manufacturers of automatic slack adjusters specify that pushrod stroke be checked by making a 90 to 100 psi application. If you have no application pressure gauge, turn the engine off and pump the reservoir pressure down to between 90 and 100 psi–then make a full application.

Automatic slack adjusters should only be adjusted or repaired by a qualified mechanic except in an emergency. Follow the manufacturer’s instructions in carrying our any adjustment.

Emergency Manual Brake Adjustment—Automatic Slack Adjusters

THESE ARE EMERGENCY PROCEDURES ONLY. A REPAIR OR REPLACEMENT MUST BE MADE AS SOON AS POSSIBLE.

Be sure that the vehicle is safely parked with the wheels blocked. The air system should be at full pressure and the spring parking brakes released.

With a typical Type 30 standard stroke brake chamber, you must adjust the brakes if pushrod measurements are:

- more than two inches using the brake application—applied stroke method.

Four types of automatic slack adjusters

Note that these are maximum measurements. You should adjust the brakes if your measurements approach these limits.

If you make an emergency adjustment of an automatic slack adjuster, be sure to record it on your daily post–trip inspection report.

It is strongly recommended that you obtain the service data books for the make of automatic slack adjusters that you are using. They contain all the information needed to keep them operating properly, including lubrication requirements, initial setup, inspection and testing. They are available where truck parts are sold.

Slack Adjusters with Hexagonal Adjusting Bolts

If the slack adjuster has a hexagonal (six-sided) adjusting bolt, the brakes may be set up by turning the adjusting bolt in a clockwise direction until the lining contacts the drum. Backing off the adjusting bolt by ½ a turn should restore running clearance. Backing off may take considerable force and may be accompanied by a ratcheting sound and feel. This is normal.

These two types of automatic slack adjusters both have hexagonal adjusting bolts.

Slack Adjusters with Square Adjusting Bolts

If the slack adjuster has a square adjusting bolt located at the bottom end of the body, do not attempt adjusting until a spring–loaded pawl that meshes with internal teeth is disengaged. These units have a ¾ inch hexagonal (hex) cap located on the slack adjuster body. Some of these hex caps are equipped with a round “button” that can be pried up approximately 1 ⁄ 32 of an inch and held, using a screwdriver. On units not equipped with the button, the hex cap, spring and pawl must be removed. With the spring and pawl disengaged, an adjustment can be made.

These brakes must be set up with a counter–clockwise turn until the lining contacts the drum. Turning the adjusting bolt ½ a turn clockwise will restore running clearance. Release the button or re–install the spring and pawl if they were removed. This type of slack adjuster has a square adjusting bolt.

Disc Brake Adjustment

There are a number of makes and models of air disc brakes, each with a different adjustment procedure. It is therefore recommended that you consult the manufacturer’s manual for adjustment or service.

Wedge Brake Adjustment

Manual adjusters:

- Hoist or jack wheels off the ground.

- Remove dust cover from adjusting slots at two places on each brake. On twin chamber units the adjusting slots are in the backing plate below the forward chamber and above the rear chamber. If star wheel adjusting bolts are not found at these positions, the brake has been assembled on the wrong side of the vehicle. The single chamber units have adjusting slots in the backing plate on each side of the chamber.

- Adjusting bolts have right–hand threads. Turning the wheel by hand, use an adjusting spoon to turn the star wheel until the shoe develops a heavy drag on the drum. Then back off the bolt to a very light drag on the drum.

- Repeat for the other shoe on that brake assembly.

- Replace the dust covers in the adjusting slots.

- Repeat the above steps on the other brake assemblies.

There is no reliable substitute for physically checking brake adjustment.

After a Brake Adjustment

At the first stop after adjusting the brakes, check each brake drum or rotor for temperature. An extra hot brake drum indicates that you have over adjusted it.

Only when all brakes are properly adjusted will the system be able to absorb the required amount of energy to bring the loaded vehicle to a safe stop under extreme conditions. Remember that poorly adjusted brakes may appear to be working at slow speeds on light air application. The only way to be sure your vehicle brakes are properly adjusted is to physically check the push rod travel at each wheel.

In-Service Checks

In some areas signs are posted in advance of steep or long downgrades. These signs indicate that the driver must stop the vehicle in the pullout area and inspect the braking system before proceeding. Check that:

- the compressor is maintaining full reservoir air pressure;

- push rod travel is within limitations on all chambers;

- there are no air leaks;

- the glad hands and the lines are secure;

- the drums, bearings and tires are not overheating;

- the trailer supply valve is operating properly.

This should be used as an in–service check only and not mistaken as a daily pre–trip air brake inspection.

The driver must be aware of the condition of the vehicle’s braking system at all times. This can be done by:

- watching the pressure gauges;

- hearing the warning signals; and

- feeling the braking response of the vehicle.

By this method of observation, the driver should be able to notice any defects developing in the braking system and be aware that service or adjustment is required.

Maintenance and Servicing of the Air Brake System

Ensuring that the vehicle is in proper condition to drive is the responsibility of everyone involved.

Preventive maintenance checks are designed to prevent mechanical failures that could result from neglect. These checks cut repair costs by detecting minor mechanical defects which would otherwise develop into major breakdowns.

Preventive maintenance may be assigned to a maintenance crew or to the driver. However the driver must ensure that the braking system is in safe operating condition before the vehicle moves.

Click Below for More Information

Air Brake Adjustment Myths

There is some misinformation about air brakes that you may hear. Most of this is not critical, but the following three myths could be dangerous, if believed.

Myth #1: Air Brake adjustment can be checked from the cab by making a full brake application and checking for an initial pressure drop of between 8–12 psi. The assumption is that as the brake chambers stroke further and further, that more air volume will be required, and this should show up on the reservoir gauges.

Fact #1: Modern trucks have very large air reservoirs, and even if all the brakes had excess pushrod travel, the pressure drop would not reach the 8–12 psi range. Also, most truck reservoir gauges do not have markings fine enough to accurately estimate such pressure changes.

Myth #2: With the brakes applied, a 90-degree angle between the centre of the slack adjuster arm and the chamber pushrod is a good indication that the brake is in correct adjustment.

Fact #2: The 90-degree angle is more dependent on the length of the chamber pushrod than on brake adjustment. Also, to prevent interference between the slack adjuster and suspension parts, some manufacturers will vary the angle up to plus or minus 10 degrees.

Myth #3: A clockwise turn of the adjusting bolt on a manual slack adjuster will set up the brakes.

Fact #3: Depending on the orientation of the slack adjuster on the brake assembly, the correct direction to set up the brakes may be clockwise, or counter-clockwise. On vehicles with tandem axles, it is common to find that one axle sets up with a clockwise turn, while the other requires a reverse direction.

Section Summary

- Why is it so critical to check slack adjustment?

- Who is ultimately responsible for the brakes on a vehicle?

- Who will be fined for operating a vehicle with brakes improperly adjusted?

- What are the dangers of operating a vehicle where the pushrod travel is barely within tolerance when the brake drums are cold?

- What items should you carry to measure and adjust slack adjusters?

- What is the first thing you should do when preparing to measure slack adjustment?

- How much pressure should you apply to the foot valve when measuring slack adjustment using the applied stroke method?

- How do you know you are turning the adjusting bolt in the correct direction when adjusting a slack adjuster?

- What is an advantage of automatic slack adjusters?

PALMER DIFFERENCE

Your Quality Equipment Partner

You run your business, we provide the equipment. It’s a partnership that works.

Additional transportation capacity is a strategic business asset, but it doesn’t have to drain your financial resources. Palmer offers flexible leasing terms that allow you to manage cash flow and position your company to take advantage of changes in your business. Unlike banks or other finance companies, we understand trailers and storage containers and have the capacity ready to fully service your equipment needs.

Palmer will provide you with consistent quality and superior service, on-demand. Palmer equipment is maintained by our experienced team to meet our stringent, 80-point inspection. You can be confident our equipment is ready when needed.

Palmer offers affordable, professional delivery and pickup, saving you the expense of transportation to and from your location.

Your Qualified Team

What truly sets us apart is the total experience – the way we put an entire company, not just a fleet of equipment, at your command. Palmer hires the mechanics, maintains the fleet, attends to the logistics, and ensures quality. To oversee your needs, a dedicated team works for you to assure our services are executed with precision.

Flexible Palmer Leasing is privately-owned and operated. We are not encumbered by corporate bureaucracy, allowing us to better serve our customers.

Responsive With credit decisions within one business day, you have the equipment you need quickly.

Personal Experienced leasing consultants will help you obtain the right equipment for your needs.

A Good Partner Palmer functions as a partner and investor in your business, providing you with the flexibility of allowing you to optimize cash flow, better serve your customers, and focus on the growth of your business.

Knowledgeable Sales, service, and support personnel have many years of experience and training.

Ready The Palmer fleet is one of the strongest and most varied in the industry; it is composed of equipment from the industry’s leading manufacturers and is large enough to support your unique needs.

You run your business, and we provide the equipment. It’s a partnership that has worked since 1965.

Customer Forms

- Credit Application

- Credit Card Agreement

- Road Insurance Requirements

- Storage Insurance Requirements

- Lease Agreement

- Personal Guarantee

Trailer Info

Maintenance

Missing Equipment

Manufacturer Information

Emergency Repair Service

Advertisement

How Air Brakes Work

- Share Content on Facebook

- Share Content on LinkedIn

- Share Content on Flipboard

- Share Content on Reddit

- Share Content via Email

Imagine it's your first week on the job as a dockhand at a rundown trucking company. Everyone is running around trying to finish loading the last pallet of cargo on the back of a huge tractor-trailer truck bound for the opposite coast. Suddenly, one of the foremen tells you to move one of the trucks out of the way so another driver can back up to the loading dock. Assuming you know how to drive such a vehicle, the foreman keeps going, but you pause -- because you don't.

Trying to please the higher-ups and to ignore the fact that you don't have a truck driver's license, you hop into the cab, close the door and turn the key. Before the diesel engine cranks, you’re startled by a mind-numbing buzzer and flashing light on the dashboard. You fire the engine, but the buzzer and light keep grabbing your attention.

You’ve driven a stick shift before, so you think you have it covered. Despite the sensory overload, you push in the clutch , grab what you think is the low gear and ease out the clutch. Instead of lurching forward as you expect, you’re greeted with a violent bang, the engine dies and you’re almost thrown through the windshield.

You restart the engine, figuring you put the truck in the wrong gear, and select what you think is the right one. Still, the buzzer and light cause havoc inside the cab. Maybe the emergency brake is still on. You don’t see any brake handle or lever that you would normally see in a car , so you decide to just let the clutch out and give it another shot.

Much to your embarrassment, the same thing happens. Out of the corner of your eye you see that same foreman hollering at you from the loading dock. Frustrated, you jump out of the cab and throw up your hands in bewilderment, as the scowling supervisor jogs toward you.

Welcome to the world of air brakes. In this article, you’ll learn how air brakes and their components work, how to maintain an air-brake system and why you couldn’t move that truck. Next, let's see how George Westinghouse got you into this situation.

George Westinghouse and Air-brake History

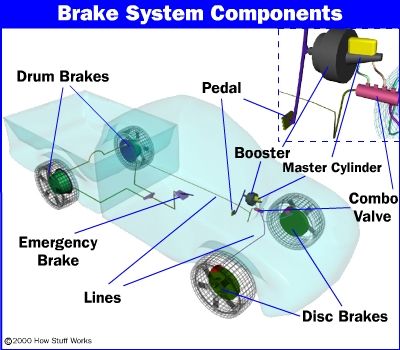

Understanding brakes, air-brake components in trucks and buses, air brakes: preventative maintenance, air brake diagram.

Air is everywhere. Hydraulic fluid isn't. Trains, buses and tractor-trailers use air-brake systems so they don’t have to rely on the hydraulic fluid in car braking systems, which can run out in the event of a leak. All of these types of transportation are weighed down by heavy passenger or cargo loads, so safety is of the utmost importance. A speeding locomotive that relied on hydraulic brakes would turn into a deadly steel bullet if the brake system suddenly busted a leak.

Before air brakes, trains used a primitive brake system that required an operator, or brakeman, in each car to apply a hand brake at the signal of the train director or engineer. This inefficient manual system was replaced by direct air-brake systems , which used an air compressor to feed air through a brake pipe into air tanks on each car. When the engineer applied these brakes, the pipe filled with air and squeezed the brakes.

In 1869, an engineer named George Westinghouse realized the importance of safety in the relatively new railroad industry and invented the first triple-valve air-brake system for railcar use. Westinghouse’s system worked the opposite way of a direct air-brake system. The triple-valve system performed three functions, thus its name. Let’s take a look at those functions.

- Charging : The system must be pressurized with air before the brakes will release. At rest, the brakes remain engaged. Once the system reaches its operating pressure, the brakes are freed and ready to use.

- Applying : As the brakes are applied, air pressure decreases. As the amount of air decreases, the valve allows air back into the reservoir tanks, while the brakes move to the applied position.

- Releasing : Once the brakes are applied and the air escapes after braking, the increased pressure releases the brakes.

Instead of using force or directed air to apply the brakes much like hydraulic fluid in our cars, the triple-valve system fills a supply tank and uses air pressure to release the brakes. In other words, the brakes in a triple-valve system remain fully engaged until air is pumped throughout the system. Pretty ingenious, considering if this type of system had a complete loss of air, the brakes would engage and stop the train. Think about that when you are zooming down the freeway and you hit the brake pedal. If your car’s brake fluid leaked out, your brakes wouldn’t work .

The triple-valve system is the basic concept at work in today’s air-brake systems in trains, buses and tractor-trailers. Let’s switch gears and learn how air brakes in roadgoing vehicles work in the next section

On June 27, 1988, a commuter train slammed into a stationary train at the Gare de Lyon station in Paris, France, killing 56 people and injuring 32 more [source: AP , National Geographic ]. The disaster occurred after a series of mistakes left the train with a greatly reduced braking ability. After a passenger inadvertently pulled the emergency brake upon her exit, the driver shut a brake valve, thinking the system had an air lock. After he released the air from the system, the train rolled freely, but the remaining cars that had a charged system didn't have enough stopping power. In a panic, the driver failed to activate the electric emergency braking system, and the train collided with a resting train at the station. If not for a brave driver in the stationary train that stayed until the collision, aiding in passenger evacuation, the death toll would have been much higher [source: AP , National Geographic ]

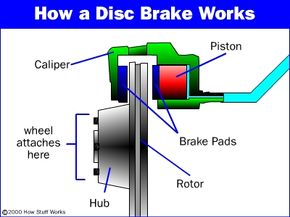

Before we learn about air brakes in road vehicles, let's look at how the brakes in your car work. Anyone who has driven a car knows when he or she pushes the brake pedal towards the floor the car slows and eventually stops. But how in the world can our foot stop a 3,000-pound (1,361-kg) car traveling down the road at high speeds?

To begin with, let's discuss the different types of brakes and then we can explore the different components. Every rolling vehicle, including trains, tractor-trailer trucks, buses and cars contain one of two types of systems. Hydraulic brakes , found in light-duty trucks and passenger cars, use hydraulic fluid or oil to operate their brakes. Air brakes, which we'll break down in the next section, use air to operate their brakes. Let's look at the differences.

In a hydraulic system, fluid is stored in a reservoir commonly referred to as a master cylinder . When you push the brake pedal, fluid is pumped through brake hoses or lines into pistons mounted on each wheel . These brake pistons either push against two brake shoes , which expand and cause friction inside a brake drum , or against a brake pad , which clamps down on a brake rotor . Below are the components in a hydraulic disc brake system.

- Brake reservoir : Contains hydraulic brake fluid

- Master cylinder : Device that pumps the fluid from the reservoir to brake lines that run throughout the vehicle

- Brake lines : Rubber or steel braided hoses that run from the master cylinder to each brake caliper

- Brake caliper : A steel housing that mounts on a fixed point of the brake rotor that contains a piston and brake pads

- Brake piston : A round rod that extends and pushes against a brake pad when hydraulic fluid is fed from the master cylinder

- Brake pad : A metal backing pad with a semi-metallic overlay that grips the steel rotor

- Brake rotor : A steel disc mounted to each wheel and hub that the pads grasp to stop the wheels from rotating

[source: Brakes ]

Here's a look at how some of the parts fit within a disc brake.

Before disc brakes, cars relied on drum brakes . The principal mechanics were the same, but drum brakes used brake shoes set inside a drum that was mounted on the hub, versus a rotor. Disc brakes increase stopping power, as they are more easily cooled and have more surface area to grasp. In addition, brake dust, which forms as the brake pads wear and decreases braking ability, is vented more easily with disc brakes than with drum brakes. For more information on disc brakes and drum brakes, read How Disc Brakes Work and How Drum Brakes Work .

Now that we understand the fundamentals of brakes in trains and cars, let's talk about the big rigs and the buses.

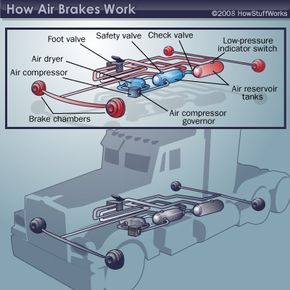

Foundation brakes are the most common air-brake systems found in trucks and buses and work the same way as in rail cars . Using the triple-valve principle, air builds up inside the brake pipes or air lines, releasing the brakes. Virtually all of the roadgoing vehicles equipped with air brakes have a graduated release system where a partial increase in pressure dictates a proportional release in brakes.

The following components are exclusive to a foundation air-brake system in a truck or a bus:

- Air compressor : Pumps the air into storage tanks to be used in the brake system

- Air compressor governor : Controls the cut-in and cut-out point of the air compressor to maintain a set amount of air in the tank or tanks

- Air reservoir tanks : Hold compressed or pressurized air to be used by the braking system

- Drain valves : Release valves in the air tanks used to drain the air when the vehicle isn't in use

- Foot valve (brake pedal) : When depressed, air is released from the reservoir tanks

- Brake chambers : Cylindrical container that houses a slack adjuster that moves a diaphragm or cam mechanism

- Push rod : A steel rod similar to a piston that connects the brake chamber to the slack adjuster. When depressed, the brakes are released. If extended, the brakes are applied.

- Slack adjusters : An arm connects the push rod to the brake s-cam to adjust the distance between the brake shoes

- Brake S-cam : An s-shaped cam that pushes brake shoes apart and against the brake drum

- Brake shoe : Steel mechanism with a lining that causes friction against the brake drum

- Return spring : A stiff spring connected to each of the brake shoes that returns the shoes to the open position when not spread by the s-cam or diaphragm.

At idle (foot off the brake and vehicle's air system charged), air pressure overcomes the diaphragm or the s-cam is in the closed position, resulting in a released brake system. As soon as you depress the brake pedal, the air pressure decreases, turning the s-cam and spreading the brake shoes against the drum. The compressor refills the reservoir tanks and when you allow the pedal to retract, the air pressure increases back to the original state.

Emergency air brakes complement standard air-brake systems and can be activated by pulling a button on the dash (near the one with the light that we saw in the introduction). Before you can drive a vehicle with air brakes, you must push in the emergency brake button to fill the system with air. As long as the emergency system is pressurized, the emergency brake will remain free. If the system has a leak, the pressure can decrease enough to engage the emergency brake. In addition, heavy trucks are often equipped with an exhaust brake that aids the braking process, but this relies on the engine, not the air-brake system.

We've learned how air brakes work. Now let's look at how to maintenance can prevent brake failure in the next section.

Have you ever wondered why trucks and buses make those funny squeaking and hissing sounds? The squeaking is the air escaping after braking and the ppssss sound is the automatic bypass safety valves at work, ensuring the air pressure remains at the correct level. Since a main advantage of air-brakes systems is their ability to use air to operate, the compressor is constantly kicking on and kicking off to refill the reservoirs with pressurized air. When the compressor builds too much air, the valves open, producing that loud hiss.

Every state in the U.S. has specific guidelines for operating a vehicle with air brakes . The tests to obtain a commercial driver’s license are demanding, as are the steps to maintain such a vehicle. Here are some steps you'll want to take before heading out on the road:

- Make sure the minimum operating pressure for a vehicle air-brake systems is no less than 85 psi (pounds per square inch) for a bus and 100 psi for a truck.

- Check that it takes no longer than two minutes for air pressure to rise from 85 psi to 100 psi at 600 to 900 rpm. (This is called the air pressure buildup rate .)

- Confirm that the correct cut-out governor pressure for the air compressor is between 120 psi and 135 psi. Cut-in pressure is 20 psi to 25 psi below cut-out pressure.

You'll also want to watch for water in the air-brake system, a byproduct of the condensed air. Air-brake lines don’t like water, especially in colder climates where ice can block air from reaching the brake mechanism and cause the wheel to lock up. To prevent this problem, many of the modern systems have automatic drain valves installed in each air tank.

Air couplers can also pose a problem. Worn rubber seals will cause air to escape. While the compressor can overcome a small leak, running compressors too hard can lead to failure. Again, as we’ve learned, air loss isn’t necessarily a bad thing, but it will mean you’re stuck. For truck drivers, getting stranded in the middle of a mountain pass probably isn't on the itinerary.

Brake sensitivity, another byproduct of air brakes, can lead to accidents, especially for inexperienced drivers. Air-brake systems are designed to work on vehicles carrying heavy loads. Have you ever wondered where all those dual skid marks on the expressway come from? That’s a product of light or empty trailers locking their rear wheels. Probably the worst fear for a truck driver is jackknifing. It’s never good when the back end of the trailer creeps up alongside the cab. Trucks traveling in rain and snow can easily jackknife if too much brake is applied.

Most modern vehicles with air brakes use a dual system . In essence, such equipped vehicles have two systems in case one should fail. Anti-lock brakes can now be found in tractor-trailer rigs and work much the same way as ABS systems found in passenger cars.

Fundamentally speaking, air brakes are efficient and reliable. However, don’t hold your breath if you’re hoping to find them in your car any time soon. Air-brakes systems occupy too much space and attention to be considered practical in cars. Just look at a Peterbilt truck as it saunters down the interstate. Have you seen the big tanks tucked behind the fuel tanks? Try finding a place for those under the hood of a Honda Civic.

If you’d like to learn more about air brakes and read some related HowStuffWorks articles, explore the links on the next page.

On April 25, 1996, a 1988 Mack cement truck collided with a small Subaru sedan in Plymouth Meeting, Pa. As the driver of the cement truck approached an intersection at the end of a downhill off ramp, his brakes failed and the truck barreled into the intersection, striking the Subaru and killing its driver. The National Transportation Safety Board investigated the incident and found several problems with the truck, notably reversed brake lines and a secondary system failure. Those two issues left the truck with only an estimated 17 percent to 21 percent of its total braking capability. Unfortunately, the driver had no idea he had a brake failure. Poor maintenance resulted in a senseless death that could have been avoided. [source: NTSB ]

Now let's put the parts together to see how air brakes work as a whole. This diagram provides both a closeup view and an example of where the brakes are located in your vehicle.

Air Brakes FAQ

How does an air brake work, who invented air brakes, what are the five components of an air brake system, why do air brakes make noise, why are air brakes not used in cars, lots more information, related articles.

- How Brakes Work

- How Anti-Lock Brakes Work

- How Disc Brakes Work

- How Drum Brakes Work .

- How Power Brakes Work

- What are the different types of brake fluid?

- When I put my car in park what really keeps it from moving?

More Great Links

- The U.S. National Transportation Safety Board

- The U.S. Department of Transportation (DOT)

- Associated Press. "Another Deadly Parisian Train Crash." The New York Times. Aug. 7, 1988. (May 20, 2008) http://query.nytimes.com/gst/fullpage.html?res=940DEFDA1638F934A3575BC0A96E948260

- California Department of Motor Vehicles. "California Commercial Driver Handbook Section 5: Air Brakes." Jan. 1, 2006. (May 21, 2008) http://www.dmv.ca.gov/pubs/cdl_htm/sec5_a.htm

- Carly, Larry. "Brake (device)." MSN Encarta. 2008. (May 17, 2008) http://encarta.msn.com/text_761555435___3/Brake_(device).html

- CDX Online eTextbook. "Braking Systems." (May 24, 2008) http://www.cdxetextbook.com/brakes/brakes.html

- CDX Online eTextbook. "Exhaust Brakes." (May 24, 2008) http://www.cdxetextbook.com/brakes/brake/systems/exhaustbrake.html

- Connor, Piers R. Railroad.net. "Air Brakes." (May 18, 2008) http://www.railroad.net/articles/railfanning/airbrakes/index.php

- National Geographic Channel. "Seconds from Disaster; Runaway Train." (May 21, 2008) http://channel.nationalgeographic.com/series/seconds-from-disaster/2389/Overview

- National Transportation Safety Board. "Highway Accident Report PB97-916202." Oct. 17, 1997. (May 19, 2008) http://ntl.bts.gov/lib/9000/9700/9762/HAR9702S.pdf

- San Diego Railway Museum. "Train Air Brake Description and History." (May 18, 2008) http://www.sdrm.org/faqs/brakes.html

- Thomson, Clive. Canadian Underwriter. "Putting the Brakes on Air Brake failure." May 2007. (May 20, 2008) http://www.canadianunderwriter.ca/Issues/ISarticle.asp?id=187245&story_id=25097143856&issue=05012007&PC=

Please copy/paste the following text to properly cite this HowStuffWorks.com article:

- Jun 14, 2021

Air Brake Pushrod Stroke - Why its so Important?

Updated: Oct 11, 2022

The brake system on a commercial motor vehicle must work well every time, under all conditions. If not, the driver’s life and the lives of others are at risk.

To effectively stop in every braking situation, all components in the air brake system, including the foundation brakes, must be properly installed, adjusted and maintained by qualified technicians. Stroke limits specified by Canadian and U.S. regulations help maintenance technicians and enforcement personnel inspect and identify brakes that may not be properly adjusting.

During day-to-day driving, a driver cannot tell how well the brakes will work during an extreme braking maneuver. The most effective way to confirm that S-cam drum brakes are within regulatory limits is to measure pushrod stroke. Pushrod stroke is the length in inches or millimeters that the pushrod travels when the brake is fully applied. If the pushrod stroke is beyond the limit in the regulation, the foundation brake may no longer be able to provide full braking force and the brake may need servicing.

Brake system violations represent the most common reason commercial motor vehicles are placed out of service during roadside inspections. When pushrod stroke exceeds the regulatory limit, a violation exists and something may be wrong in the foundation brake system or with the slack adjuster.

By following manufacturers’ recommended foundation brake maintenance intervals (for lubrication, lining replacement, wear tolerances, etc.), regularly measuring the pushrod stroke and proactively addressing issues immediately, crash risk can be mitigated, safety ratings may improve, and the chances of a violation or out-of-service order can be reduced.

Keeping a brake chamber pushrod within regulatory stroke limits ensures there is sufficient pushrod travel to apply full force to the foundation brake under all operating conditions. The limits are based on the size of the brake chamber and whether the chamber is a standard or long-stroke design. See Clamp Type - Air Brake Adjustment Limit Chart.

Pushrod stroke that exceeds regulatory limits not only violates federal, state, provincial or territorial regulations but, more importantly, results in a decline in the braking force – eventually to zero – provided by the foundation brake, which will increase the distance it takes to stop the vehicle.

Vehicles manufactured in after Oct. 20, 1994 must be equipped with self-adjusting brake adjusters (SABAs) to automatically account for normal brake system wear. Manual brake adjusters are only permitted on legacy vehicles manufactured prior to the dates above and must be regularly adjusted by hand.

The use of SABAs has helped to significantly reduce the rate of out-of- service brake violations. However, even with properly working SABAs, abnormal or excessive wear or broken components can result in excessive pushrod stroke and must be properly serviced.

How to Correctly Measure the Brake Chamber Stroke:

To measure chamber pushrod stroke, you will need a ruler, chalk, flashlight, eye protection, pencil and paper. You will also need another person to apply the service brakes. The procedure is as follows:

Step One – Ensure the vehicle is in a safe location and make sure the wheels are properly chocked to prevent rolling. Release the spring brakes. Confirm your dash gauge indicates 90 to 100 PSI supply pressure in the air brake system reservoirs. Then, shut off the engine. Note: Supply reservoir pressure exceeding 110 PSI will result in incorrect pushrod stroke assessments.

Step Two – Visually inspect each brake and confirm it is in the normal released position with nothing wrong or out of place. Mark each pushrod to establish a reference starting location. This should be level with where the pushrod exits the brake chamber or the chamber mounting bracket. Note where the pushrod mark started out and where moves to with brake application, then measure the difference in the next step. See Measuring Pushrod Travel.

Step Three – Have the other person press and hold the service brakes (pushing the brake pedal all the way down until it stops) while you measure and record the distance each pushrod mark moved (or “stroked”).

Note: It is normal for pressure to drop slightly as brakes are applied. If multiple brake applications cause the pressure to drop below 90 PSI, pause the procedure to rebuild reservoir pressure to 90 to 100 PSI, then resume with the engine off.

Step Four – Compare your recorded pushrod stroke values with the stroke limits in the regulation for your brake chambers. See Clamp Type - Air Brake Adjustment Limit Chart .

If any chamber stroke measurement is near, at or beyond the prescribed regulatory stroke limit for your chamber type or size, the foundation brake, brake chamber, SABA, drum and wheel-end need to be inspected in more detail and serviced as soon as possible.

If any pushrod stroke measurement exceeds the prescribed stroke limit, a violation exists and braking force is greatly reduced.

Important Information and Facts Regarding Self-Adjusting Brake Adjusters

Self-adjusting brake adjusters – SABAs should not be manually adjusted; they will do so automatically. If a chamber with a SABA has excessive stroke, there is a problem with the foundation brake, the drum, the SABA itself or other components. The entire wheel end (chamber, SABA, drum, hub and other hardware) should be inspected and serviced by an authorized brake technician as soon as possible.

A manual readjustment may temporarily improve the stroke length, but it can cause damage and does not fix the underlying problem. The stroke violation will return within a few brake applications and, most importantly, stopping ability may be significantly impaired.

When SABAs exceed the regulation limit, consider the following before adjusting the brakes:

Drivers may be legally prohibited from adjusting SABAs in some jurisdictions.

The motor carrier may prohibit the driver from adjusting SABAs.

Do not readjust a SABA unless you have been specially trained to do so.

Manually adjusting a SABA improperly can damage the adjuster. The manufacturer’s instructions must be precisely followed.

The brake chamber will return to the excessive stroke condition until the cause of the problem is repaired. Excessive stroke can return quickly, in just a few brake applications.

If the driver readjusts the brake chamber stroke, he or she must continue to monitor the brake chamber stroke and report any excessive stroke problems to the motor carrier or service provider.

Be sure that any technician hired to correct an excessive brake chamber stroke is qualified and will fix the underlying cause.

If a brake chamber with SABAs exhibits excessive stroke, some of the contributing causes could include worn or seized clevis pin connections, worn S-cam bushings, cracked chamber bracket or cam tube welds, worn rollers, cracked drums, worn linings, worn drums and/or loose mounting hardware. A trained brake technician should diagnose and correct the underlying problem(s).

Charting and Tracking Chamber Stoke Travel in the Vehicle Maintenance Record

Tracking and maintaining a record of pushrod travel will help assist the fleet management in identifying brake wear periods for individual vehicles or specific routes which may cause additional brake wear.

Many fleets have found success in preventing violations by tracking brake chamber stroke measurements at each wheel as part of their maintenance programs. This involves recording pushrod stroke each time it is measured. See Stroke Travel Chart

For example, consider a truck-tractor with Type 24L chambers on the steer axle and Type 30LS on the drive axles. Stroke limits in the regulation for Type 24L and Type 30LS are 2 inches and 2 1/2 inches, respectively.

The table below shows pushrod stroke measurements recorded on three occasions. Note the circled entries show one brake at the regulatory limit (it will need service soon) and another exceeding the regulatory limit (it is a violation and must be serviced). This table can be expanded to account for all axles in a vehicle or combination.

Make sure to check out our online DOT Training, DOT University ! We currently are offering Reasonable Suspicion for Supervisors , Cargo Securement and Defensive Driving . In the coming months we plan on releasing Pre/Post Trip Inspection, Designated Employer Representative, and Appendix A.

Until then , check out our other blogs or follow us on Facebook , Twitter , and Instagram to be the first to know when new classes are made available or for other updates like this! You can also opt-in to our newsletter for exclusive offers, regulation changes, and industry news!

Stay Off The Radar!

#brakes #airbrakes #tractortrailer #FRCS #Compliance #DOT

Recent Posts

Getting zero violations during a roadside inspection

Securement Devices and Their Limits

10 Safety Tips for Commercial Drivers

EZ Chek - Air Brake Stroke Indicators

Air Brake Stroke Indicators

Various packaging quantity options and packaging assortments available, hole for push rod size either 5/8" common or 1/2", large and small diameters are 1-3/4" or 1-3/8", easy way to check air brake adjustment for trailer and drive axles, trailer & drive axle applications, stays on the vehicle, available in bulk at discounted pricing (200 +), you may also like....

Net Orders Checkout

Shipping address, shipping methods.

× You are using an outdated browser. Please upgrade your browser to improve your experience.

Shopping Cart

Your cart is currently empty., meritor m820625 simplecheck air brake stroke indicator tool, 5/8" pushrods, 1-3/4" od, availability, product details.

Cross References: M820625, 650-M820625 A cross reference listing means that this item should be a suitable replacement for the part numbers listed. You should check the description to be sure it will work in your application.

Meritor M820750 SimpleCheck Air Brake Stroke Indicator Tool, 3/4" Pushrods, 1-3/4" OD

Part# 650-M820750

$1.66 USD Not Yet Rated | Write the First Review

Meritor M810500 SimpleCheck Stroke Indicator, 1/2" Pushrods, 1-3/8" OD

Part# 650-M810500

$1.70 USD Not Yet Rated | Write the First Review

Meritor M810625 SimpleCheck Stroke Indicator, 5/8" Pushrods, 1-3/8" OD

Part# 650-M810625

Be the first to rate this item!

Write Review

Copyright © 2024 AnythingTruck.com.

2018 Primetime Emmy & James Beard Award Winner

In Transit: Notes from the Underground

Jun 06 2018.

Spend some time in one of Moscow’s finest museums.

Subterranean commuting might not be anyone’s idea of a good time, but even in a city packing the war-games treasures and priceless bejeweled eggs of the Kremlin Armoury and the colossal Soviet pavilions of the VDNKh , the Metro holds up as one of Moscow’s finest museums. Just avoid rush hour.

The Metro is stunning and provides an unrivaled insight into the city’s psyche, past and present, but it also happens to be the best way to get around. Moscow has Uber, and the Russian version called Yandex Taxi , but also some nasty traffic. Metro trains come around every 90 seconds or so, at a more than 99 percent on-time rate. It’s also reasonably priced, with a single ride at 55 cents (and cheaper in bulk). From history to tickets to rules — official and not — here’s what you need to know to get started.

A Brief Introduction Buying Tickets Know Before You Go (Down) Rules An Easy Tour

A Brief Introduction

Moscow’s Metro was a long time coming. Plans for rapid transit to relieve the city’s beleaguered tram system date back to the Imperial era, but a couple of wars and a revolution held up its development. Stalin revived it as part of his grand plan to modernize the Soviet Union in the 1920s and 30s. The first lines and tunnels were constructed with help from engineers from the London Underground, although Stalin’s secret police decided that they had learned too much about Moscow’s layout and had them arrested on espionage charges and deported.

The beauty of its stations (if not its trains) is well-documented, and certainly no accident. In its illustrious first phases and particularly after the Second World War, the greatest architects of Soviet era were recruited to create gleaming temples celebrating the Revolution, the USSR, and the war triumph. No two stations are exactly alike, and each of the classic showpieces has a theme. There are world-famous shrines to Futurist architecture, a celebration of electricity, tributes to individuals and regions of the former Soviet Union. Each marble slab, mosaic tile, or light fixture was placed with intent, all in service to a station’s aesthetic; each element, f rom the smallest brass ear of corn to a large blood-spattered sword on a World War II mural, is an essential part of the whole.

The Metro is a monument to the Soviet propaganda project it was intended to be when it opened in 1935 with the slogan “Building a Palace for the People”. It brought the grand interiors of Imperial Russia to ordinary Muscovites, celebrated the Soviet Union’s past achievements while promising its citizens a bright Soviet future, and of course, it was a show-piece for the world to witness the might and sophistication of life in the Soviet Union.

It may be a museum, but it’s no relic. U p to nine million people use it daily, more than the London Underground and New York Subway combined. (Along with, at one time, about 20 stray dogs that learned to commute on the Metro.)

In its 80+ year history, the Metro has expanded in phases and fits and starts, in step with the fortunes of Moscow and Russia. Now, partly in preparation for the World Cup 2018, it’s also modernizing. New trains allow passengers to walk the entire length of the train without having to change carriages. The system is becoming more visitor-friendly. (There are helpful stickers on the floor marking out the best selfie spots .) But there’s a price to modernity: it’s phasing out one of its beloved institutions, the escalator attendants. Often they are middle-aged or elderly women—“ escalator grandmas ” in news accounts—who have held the post for decades, sitting in their tiny kiosks, scolding commuters for bad escalator etiquette or even bad posture, or telling jokes . They are slated to be replaced, when at all, by members of the escalator maintenance staff.

For all its achievements, the Metro lags behind Moscow’s above-ground growth, as Russia’s capital sprawls ever outwards, generating some of the world’s worst traffic jams . But since 2011, the Metro has been in the middle of an ambitious and long-overdue enlargement; 60 new stations are opening by 2020. If all goes to plan, the 2011-2020 period will have brought 125 miles of new tracks and over 100 new stations — a 40 percent increase — the fastest and largest expansion phase in any period in the Metro’s history.

Facts: 14 lines Opening hours: 5 a.m-1 a.m. Rush hour(s): 8-10 a.m, 4-8 p.m. Single ride: 55₽ (about 85 cents) Wi-Fi network-wide

Buying Tickets

- Ticket machines have a button to switch to English.

- You can buy specific numbers of rides: 1, 2, 5, 11, 20, or 60. Hold up fingers to show how many rides you want to buy.

- There is also a 90-minute ticket , which gets you 1 trip on the metro plus an unlimited number of transfers on other transport (bus, tram, etc) within 90 minutes.

- Or, you can buy day tickets with unlimited rides: one day (218₽/ US$4), three days (415₽/US$7) or seven days (830₽/US$15). Check the rates here to stay up-to-date.

- If you’re going to be using the Metro regularly over a few days, it’s worth getting a Troika card , a contactless, refillable card you can use on all public transport. Using the Metro is cheaper with one of these: a single ride is 36₽, not 55₽. Buy them and refill them in the Metro stations, and they’re valid for 5 years, so you can keep it for next time. Or, if you have a lot of cash left on it when you leave, you can get it refunded at the Metro Service Centers at Ulitsa 1905 Goda, 25 or at Staraya Basmannaya 20, Building 1.

- You can also buy silicone bracelets and keychains with built-in transport chips that you can use as a Troika card. (A Moscow Metro Fitbit!) So far, you can only get these at the Pushkinskaya metro station Live Helpdesk and souvenir shops in the Mayakovskaya and Trubnaya metro stations. The fare is the same as for the Troika card.

- You can also use Apple Pay and Samsung Pay.

Rules, spoken and unspoken

No smoking, no drinking, no filming, no littering. Photography is allowed, although it used to be banned.

Stand to the right on the escalator. Break this rule and you risk the wrath of the legendary escalator attendants. (No shenanigans on the escalators in general.)

Get out of the way. Find an empty corner to hide in when you get off a train and need to stare at your phone. Watch out getting out of the train in general; when your train doors open, people tend to appear from nowhere or from behind ornate marble columns, walking full-speed.

Always offer your seat to elderly ladies (what are you, a monster?).

An Easy Tour

This is no Metro Marathon ( 199 stations in 20 hours ). It’s an easy tour, taking in most—though not all—of the notable stations, the bulk of it going clockwise along the Circle line, with a couple of short detours. These stations are within minutes of one another, and the whole tour should take about 1-2 hours.

Start at Mayakovskaya Metro station , at the corner of Tverskaya and Garden Ring, Triumfalnaya Square, Moskva, Russia, 125047.

1. Mayakovskaya. Named for Russian Futurist Movement poet Vladimir Mayakovsky and an attempt to bring to life the future he imagined in his poems. (The Futurist Movement, natch, was all about a rejecting the past and celebrating all things speed, industry, modern machines, youth, modernity.) The result: an Art Deco masterpiece that won the National Grand Prix for architecture at the New York World’s Fair in 1939. It’s all smooth, rounded shine and light, and gentle arches supported by columns of dark pink marble and stainless aircraft steel. Each of its 34 ceiling niches has a mosaic. During World War II, the station was used as an air-raid shelter and, at one point, a bunker for Stalin. He gave a subdued but rousing speech here in Nov. 6, 1941 as the Nazis bombed the city above.

Take the 3/Green line one station to:

2. Belorusskaya. Opened in 1952, named after the connected Belarussky Rail Terminal, which runs trains between Moscow and Belarus. This is a light marble affair with a white, cake-like ceiling, lined with Belorussian patterns and 12 Florentine ceiling mosaics depicting life in Belarussia when it was built.

Transfer onto the 1/Brown line. Then, one stop (clockwise) t o:

3. Novoslobodskaya. This station was designed around the stained-glass panels, which were made in Latvia, because Alexey Dushkin, the Soviet starchitect who dreamed it up (and also designed Mayakovskaya station) couldn’t find the glass and craft locally. The stained glass is the same used for Riga’s Cathedral, and the panels feature plants, flowers, members of the Soviet intelligentsia (musician, artist, architect) and geometric shapes.

Go two stops east on the 1/Circle line to:

4. Komsomolskaya. Named after the Komsomol, or the Young Communist League, this might just be peak Stalin Metro style. Underneath the hub for three regional railways, it was intended to be a grand gateway to Moscow and is today its busiest station. It has chandeliers; a yellow ceiling with Baroque embellishments; and in the main hall, a colossal red star overlaid on golden, shimmering tiles. Designer Alexey Shchusev designed it as an homage to the speech Stalin gave at Red Square on Nov. 7, 1941, in which he invoked Russia’s illustrious military leaders as a pep talk to Soviet soldiers through the first catastrophic year of the war. The station’s eight large mosaics are of the leaders referenced in the speech, such as Alexander Nevsky, a 13th-century prince and military commander who bested German and Swedish invading armies.

One more stop clockwise to Kurskaya station, and change onto the 3/Blue line, and go one stop to:

5. Baumanskaya. Opened in 1944. Named for the Bolshevik Revolutionary Nikolai Bauman , whose monument and namesake district are aboveground here. Though he seemed like a nasty piece of work (he apparently once publicly mocked a woman he had impregnated, who later hung herself), he became a Revolutionary martyr when he was killed in 1905 in a skirmish with a monarchist, who hit him on the head with part of a steel pipe. The station is in Art Deco style with atmospherically dim lighting, and a series of bronze sculptures of soldiers and homefront heroes during the War. At one end, there is a large mosaic portrait of Lenin.

Stay on that train direction one more east to:

6. Elektrozavodskaya. As you may have guessed from the name, this station is the Metro’s tribute to all thing electrical, built in 1944 and named after a nearby lightbulb factory. It has marble bas-relief sculptures of important figures in electrical engineering, and others illustrating the Soviet Union’s war-time struggles at home. The ceiling’s recurring rows of circular lamps give the station’s main tunnel a comforting glow, and a pleasing visual effect.

Double back two stops to Kurskaya station , and change back to the 1/Circle line. Sit tight for six stations to:

7. Kiyevskaya. This was the last station on the Circle line to be built, in 1954, completed under Nikita Khrushchev’ s guidance, as a tribute to his homeland, Ukraine. Its three large station halls feature images celebrating Ukraine’s contributions to the Soviet Union and Russo-Ukrainian unity, depicting musicians, textile-working, soldiers, farmers. (One hall has frescoes, one mosaics, and the third murals.) Shortly after it was completed, Khrushchev condemned the architectural excesses and unnecessary luxury of the Stalin era, which ushered in an epoch of more austere Metro stations. According to the legend at least, he timed the policy in part to ensure no Metro station built after could outshine Kiyevskaya.

Change to the 3/Blue line and go one stop west.

8. Park Pobedy. This is the deepest station on the Metro, with one of the world’s longest escalators, at 413 feet. If you stand still, the escalator ride to the surface takes about three minutes .) Opened in 2003 at Victory Park, the station celebrates two of Russia’s great military victories. Each end has a mural by Georgian artist Zurab Tsereteli, who also designed the “ Good Defeats Evil ” statue at the UN headquarters in New York. One mural depicts the Russian generals’ victory over the French in 1812 and the other, the German surrender of 1945. The latter is particularly striking; equal parts dramatic, triumphant, and gruesome. To the side, Red Army soldiers trample Nazi flags, and if you look closely there’s some blood spatter among the detail. Still, the biggest impressions here are the marble shine of the chessboard floor pattern and the pleasingly geometric effect if you view from one end to the other.

Keep going one more stop west to:

9. Slavyansky Bulvar. One of the Metro’s youngest stations, it opened in 2008. With far higher ceilings than many other stations—which tend to have covered central tunnels on the platforms—it has an “open-air” feel (or as close to it as you can get, one hundred feet under). It’s an homage to French architect Hector Guimard, he of the Art Nouveau entrances for the Paris M é tro, and that’s precisely what this looks like: A Moscow homage to the Paris M é tro, with an additional forest theme. A Cyrillic twist on Guimard’s Metro-style lettering over the benches, furnished with t rees and branch motifs, including creeping vines as towering lamp-posts.

Stay on the 3/Blue line and double back four stations to:

10. Arbatskaya. Its first iteration, Arbatskaya-Smolenskaya station, was damaged by German bombs in 1941. It was rebuilt in 1953, and designed to double as a bomb shelter in the event of nuclear war, although unusually for stations built in the post-war phase, this one doesn’t have a war theme. It may also be one of the system’s most elegant: Baroque, but toned down a little, with red marble floors and white ceilings with gilded bronze c handeliers.

Jump back on the 3/Blue line in the same direction and take it one more stop:

11. Ploshchad Revolyutsii (Revolution Square). Opened in 1938, and serving Red Square and the Kremlin . Its renowned central hall has marble columns flanked by 76 bronze statues of Soviet heroes: soldiers, students, farmers, athletes, writers, parents. Some of these statues’ appendages have a yellow sheen from decades of Moscow’s commuters rubbing them for good luck. Among the most popular for a superstitious walk-by rub: the snout of a frontier guard’s dog, a soldier’s gun (where the touch of millions of human hands have tapered the gun barrel into a fine, pointy blade), a baby’s foot, and a woman’s knee. (A brass rooster also sports the telltale gold sheen, though I am told that rubbing the rooster is thought to bring bad luck. )

Now take the escalator up, and get some fresh air.

R&K Insider

Join our newsletter to get exclusives on where our correspondents travel, what they eat, where they stay. Free to sign up.

21 Things to Know Before You Go to Moscow

Featured city guides.

Most Beautiful Metro Stations in Moscow

Visiting Moscow? Get yourself a metro card and explore Moscow’s beautiful metro stations. Moscow’s world-famous metro system is efficient and a great way to get from A to B. But there is more to it; Soviet mosaic decorations, exuberant halls with chandeliers, colourful paintings and immense statues. Moscow’s metro is an attraction itself, so take half a day and dive into Moscow’s underground!

The best thing to do is to get on the brown circle (number 5) line since the most beautiful metro stations are situated on this line. The only exception is the metro stop Mayakovskaya one the green line (number 2). My suggestion is to get a map, mark these metro stops on there and hop on the metro. It helps to get an English > Russian map to better understand the names of the stops. At some of the metro stops, the microphone voice speaks Russian and English so it’s not difficult at all.

Another thing we found out, is that it’s worth taking the escalator and explore the other corridors to discover how beautiful the full station is.

Quick hotel suggestion for Moscow is the amazing Brick Design Hotel .

These are my favourite metro stations in Moscow, in order of my personal preference:

1. Mayakovskaya Station

The metro station of Mayakovskaya looks like a ballroom! Wide arches, huge domes with lamps and mosaic works make your exit of the metro overwhelming. Look up and you will see the many colourful mosaics with typical Soviet pictures. Mayakovskaya is my personal favourite and is the only stop not on the brown line but on the green line.

2. Komsomolskaya Station

Komsomolskaya metro station is famous for its yellow ceiling. An average museum is nothing compared to this stop. Splendour all over the place, black and gold, mosaic – again – and enormous chandeliers that made my lamp at home look like a toy.

3. Novoslobodskaya Station

The pillars in the main hall of Novoslobodskaya metro station have the most colourful stained glass decorations. The golden arches and the golden mosaic with a naked lady holding a baby in front of the Soviet hammer and sickle, make the drama complete.

4. Prospect Mira Station

The beautiful chandeliers and the lines in the ceiling, make Prospekt Mira an architectural masterpiece.

5. Belorusskaya Station

Prestigious arches, octagonal shapes of Socialistic Soviet Republic mosaics. The eyecatcher of Belorusskaya metro station, however, is the enormous statue of three men with long coats, holding guns and a flag.

6. Kiyevskaya Station

The metro station of Kiyevskaya is a bit more romantic than Belorusskaya and Prospect Mira. Beautiful paintings with classical decorations.

7. Taganskaya Station

At the main hall Taganskaya metro station you will find triangle light blue and white decorations that are an ode to various Russians that – I assume – are important for Russian history and victory. There is no need to explore others halls of Taganskaya, this is it.

8. Paveletskaya Station

Another and most definitely the less beautiful outrageous huge golden mosaic covers one of the walls of Paveletskaya. I would recommend taking the escalator to the exit upstairs to admire the turquoise dome and a painting of the St Basil’s Cathedral in a wooden frame.

Travelling with Moscow’s metro is inexpensive. You can have a lot of joy for just a few Rubbles.

- 1 single journey: RMB 50 – € 0,70

- 1 day ticket: RMB 210 – € 2,95

Like to know about Moscow, travelling in Russia or the Transsiberian Train journey ? Read my other articles about Russia .

- 161 Shares

You may also like

Hunting for the best coffee in irkutsk, amsterdam forest: a day trip for nature..., a romantic amalfi coast road trip itinerary, complete weekend city guide to maastricht, olkhon island: siberian sunsets over lake baikal, 8 great reasons to visit mongolia in..., trans-siberian railway travel guide, all you need to know for your..., food & drinks in moscow, why we love grünerløkka in oslo.

Wow! It is beautiful. I am still dreaming of Moscow one day.

It’s absolutely beautiful! Moscow is a great city trip destination and really surprised me in many ways.

My partner and I did a self guided Moscow Metro tour when we were there 2 years ago. So many breathtaking platforms…I highly recommend it! Most of my favorites were along the Brown 5 line, as well. I also loved Mayakovskaya, Arbatskaya, Aleksandrovski Sad and Ploshchad Revolyutsii. We’re heading back in a few weeks and plan to do Metro Tour-Part 2. We hope to see the #5 stations we missed before, as well as explore some of the Dark Blue #3 (Park Pobedy and Slavyansky Bul’var, for sure), Yellow #8 and Olive #10 platforms.

That’s exciting Julia! Curious to see your Metro Tour-Part 2 experience and the stations you discovered.

Leave a Comment Cancel Reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Bahasa Indonesia

- Slovenščina

- Science & Tech

- Russian Kitchen

How do air taxis operate in Moscow?

Currently, only passenger planes at an altitude greater than 8,100 meters (26,574ft), the Ministry of Emergency Situations and the Federal Protective Service helicopters, as well as some other government services’ and bodies’ aircraft are allowed to fly over Moscow. And yet, if you really need it, you can use an air taxi. How convenient will it be is a different question entirely.

Departing from the region

To fly over the capital, you need to have special permission and such permission is not issued to business aviation. So, you won’t be able to take off or land on the territory of the city itself. All air taxi helipads are located beyond the Moscow Ring Road (MKAD) , while the flight path can’t cross the ring road either.

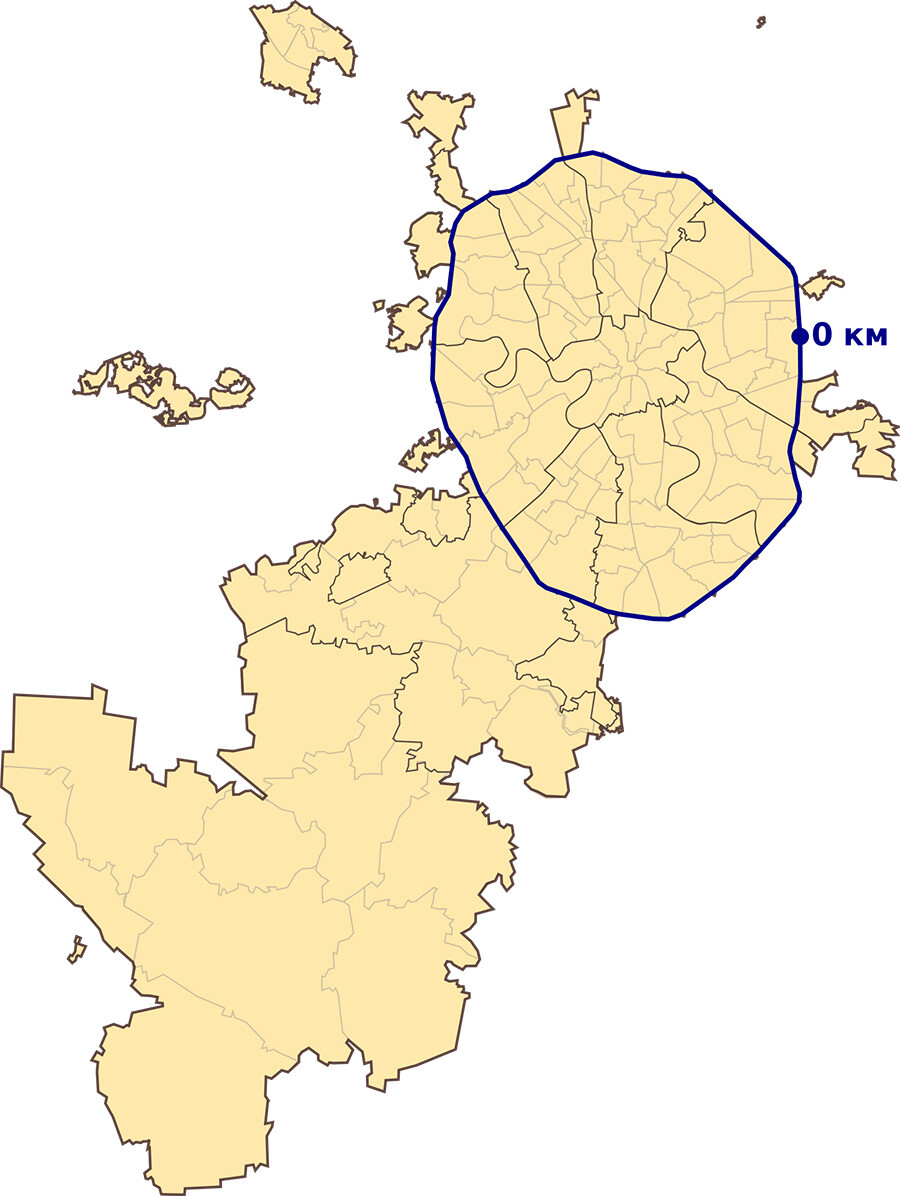

MKAD on the map.

It’s convenient to use an air taxi if you live or are located in the region and you urgently need to go to the airport, to another place outside the city or to the closest settlement. But, if the matter is the speed of transportation and avoiding traffic – alas, an aerotaxi can’t help you!

How to use it?

If you still have a need for air taxi services, then, first of all, you need to choose the company with whom to fly. The majority of air taxi companies provide the same helicopter options, they only differ in price and location. Considering that the helipads are located outside the city, it’s logical to just choose the closest one to you/to get to.

Booking conditions vary from one service to another. It’s best to book your helicopter in advance, at least 5-6 hours before departure. But some services are ready to provide you with an aircraft an hour after contacting them. In any case, you will be required to state your route, the amount of passengers and baggage. On average, Moscow services offer helicopters that can take 3 to 10 people on board.

Upon arriving at a helipad, you will be required to show your passport and you’ll be registered for the flight. On average, this process takes about 15 minutes. After that, you board the helicopter and depart for your destination.

The price of a flight varies from one provider to another. The lowest price for a 60-minute flight that we managed to find is 30,000 rubles (approx. $338) in a Robinson R44 helicopter for three passengers. But, the service staff explained that this price was quite conditional. There’s no fixed price for a flight, since when calculating the price, the model of the hired helicopter, the amount of passengers and baggage, the route and the location of the available aircraft on the specified date and time (the air taxi might have to be transported from one helipad to another) have to be taken into consideration.

Any downsides?