Form Traveller System Bridge Construction: Out-spanning Traditional Methods

The use of form traveller systems offers significant cost savings for bridge construction projects throughout the world. We've partnered with Miguel Barreto from ConstruGomes of Portugal to highlight the key aspects of form traveller systems: how they offer cost advantages over traditional construction systems, in what situations they can best be utilized, and how they function.

Form Traveller Bridge Construction

Form traveller specifics.

Form travellers can be employed during cantilevered concrete girder construction when a bridge pier can be used as a starting point. Opposite directions of span construction are facilitated by using the top of a pier as the initial anchor point for two separate form travellers (each pair of form travellers operates as a unit). Cantilevered construction is allowed by moving each pair of form travellers farther away from a pier in tandem. The weight is therefore always balanced, and the static forces on the pier maintain equilibrium. The incremental movement of each pair of form travellers is the critical path to project completion.

Work progress is limited to span increments of approximately 5 m (approx. 16') or 400 tons per week on each side of a pier. However, the key advantage of form travellers is their ability to span great distances in remote locations. If the contractor can access the piers, the bridge can generally be built with form travellers, including angled bridge decks with varying turn radii. Form travellers are preferred for building spans over deep valleys, waterways, and roads where access from the ground is a challenge and the number of piers is limited (especially for the central span).

- Form Traveller Delivery: Form traveller equipment can be trucked to the job site in multiple shipments or barged to the site if a bridge is being constructed over a navigable waterway.

- Form Traveller Operation and Training: Form travellers are powered by a hydraulic system, requiring the crews that operate them to receive specific training. The structural framework of the form traveller moves forward on rails anchored to the previously constructed span segments. The individual steel structural members of each form traveller are connected with pins to facilitate mobilization/demobilization.

- Form Traveller Installation: Form traveller equipment is assembled on the ground, and segments are then lifted by crane to their starting points on a specific bridge pier. Demobilization follows the same process in reverse. Sections are placed on the ground by crane and further disassembled into shippable parts.

Form Travellers vs. Traditional Construction

The main advantage of form travellers over other construction methods is that they allow for longer and wider spans to be built in challenging site conditions. Form travellers are better suited for bridge designs involving fewer piers because they can span much greater distances than other methods. This chart generically summarizes the maximum spans, widths, and timelines allowed by various concrete bridge construction techniques.

Moving Scaffolding Systems (MSS)

Moving scaffolding systems (MSS) cannot take full advantage of cantilevered construction techniques as compared to form travellers. Customized (expensive) MSS equipment is required for bridge decks greater than 20 m (approx. 65'). Moving scaffolding systems can be more cost-effective for long bridges with equal repeated spans (or multiple spans) because it is generally a quicker method: 30–60 m (approx. 98–196') span every week, or 60–90 m (approx. 196–295') span every two weeks. For bridge decks with a substantial turn radius, the MSS become less easy to operate. The MSS structure has to extend outward and move around constructed bridge piers as shown in this video .

Incremental Launching

Incremental launching is preferred for long straight bridge spans or those with a large and constant turn radius. This method becomes less feasible when the design requires an angled bridge deck relative to the horizon or a flat deck with a varying turn radius. The placement of each span increment is limited by the size of the hydraulic system pushing each span segment into place. Initial installation costs of the launching equipment (cables, hydraulics, rollers, etc.) is high, generally becoming more cost-effective as total bridge lengths approach 400 m (approx. 1,312'). It is usually good for small wide bridge decks that can be built in consistent segments, such as railroad bridges. It is also a good option in places where the bridge is high because the contractor doesn't need to use cranes or transports along the bridge to place deck segments. Concrete and steel materials are staged at a consistent location, so the system works similarly to a production factory.

Pre-Cast Materials

Pre-cast construction is often not suitable for larger spans. The length of the pre-cast concrete members is limited by factory equipment, the behavior of formed concrete, and shipping considerations. The use of pre-cast members is not feasible in some remote areas due to poor access roads. Transporting and elevating pre-cast members with cranes can be particularly challenging for bridge projects with poor access, rivers, or low support conditions. The higher a project’s bridge piers, the higher the cost of crane operations (i.e., larger crane equipment is required).

Heavy Propping and Traditional Scaffold Formwork

When the bridge spans are located at significant heights above grade, traditional formwork becomes no longer feasible since it requires bracing to ground. It becomes more labor-intensive and tedious as span lengths and pier heights increase. ConstruGomes has used heavy propped formwork up to only 40 m (approx. 131') of bridge span and height. These systems are normally limited to a height of 40 m because of material limitations and safety considerations. The spans can be large because they can have multiple support towers on the ground. The limit of 40 m of span is between a set of propping towers only.

Self-Climbing Formwork

Self-climbing formwork operates similarly to form travellers but builds piers vertically in increments as opposed to bridge decks laterally. Self-climbing formwork is installed at grade and can be used to construct the entire height of a new cast-in-place concrete pier. Lifts of up to 5 m (approx. 15') every 2–3 days can be achieved. Self-climbing formwork needs a constructed pier height of only 1 m (approx. 3') to begin operations.

Image Gallery

This image gallery below of ConstruGomes projects in the Marao Mountains and the Azores highlights their use of form travellers and self-climbing formwork in state-of-the-art bridge construction.

Like this article? Sign up for our monthly newsletter and get the latest updates!

Andrew Kimos

Andrew Kimos completed the civil engineering programs at the U.S. Coast Guard Academy (B.S. 1987) and the University of Illinois (M.S. 1992) and is a registered Professional Engineer in the state of Wisconsin. He served as a design engineer, construction project manager, facilities engineer, and executive leader in the Coast Guard for over 20 years. He worked as a regional airline pilot in the western U.S. before joining the Buildipedia.com team as Operations Channel Producer.

Latest from Andrew Kimos

- Case Study: Water Quality Retrofit and Retaining Wall Remediation

- Construction Documents Technology Proves Cost-Effective

- In-Situ Pipe Repairs Save Time and Money

- In Situ Pipe Repairs Save Time and Money

- U.S. Infrastructure: Drinking Water

At Home Topics

- Everyday DIY with Jeff Wilson

- 60 Simple Seconds

- Jeff Wilson Everyday DIY Blog

- Rehabitat with Rachael Ranney

- Design & Remodeling

- Landscaping

- HVAC | Electrical | Plumbing

- Walls | Windows | Doors

AEC Pros Topics

- Featured Architecture

- Design News

- Solar Decathlon

- Construction Materials & Methods

- From the Job Site

- Engineering News

- Public Infrastructure

- Facilities Ops & Maintenance

- Urban Planning

- CSI Project Solutions

Knowledgebase

- Division 02 Existing Conditions

- Division 03 Concrete

- Division 04 Masonry

- Division 05 Metals

- Division 06 Wood, Plastics, and Composites

- Division 07 Thermal and Moisture Protection

- Division 08 Openings

- Division 09 Finishes

- Division 10 Specialties

- Division 11 Equipment

- Division 12 Furnishings

- Division 13 Special Construction

- Division 14 Conveying Equipment

- Division 21 Fire Suppression

- Division 22 Plumbing

- Division 23 HVAC

- Division 26 Electrical

- Division 27 Communications

- Division 28 Electronics Safety and Security

- Division 31 Earthwork

- Division 32 Exterior Improvements

- Division 33 Utilities

- Find Us on Twitter

- Find Us on Facebook

- Find Us on YouTube

- Find Us on Pinterest

- Editorial Calendar

- Advertising

- Writers Guidelines

- Terms and Conditions

Overhead Form Traveller

- Design, fabrication, delivery and technical assistance to the new equipment

What Is Overhead Form Traveller

The Form Traveller is a temporary support structure supporting the weigh of the bridge and viaduct deck segments cast in situ built by the cantilever method from the pier head to the center of the span.

Safe, Typical, Adjustable

- Adjustable to the variations of segment length, cross section height, web thickness, and deck width

- Easy to fit almost any deck cross section

MIDAS software calculation

- Reduced weight, saving prestressing in the deck construction phase

- Easy to transport

Save Cost to Be Reused

- Easy to assemble, launch-back and disassemble

- Reusable multiple times

Pre-test and Pre-load

- Reduced deformations

- Easy to adjust the height for the curves

Form Traveller Frame System

1. Main frame system

- Upper bracing

- Lower bracing

- Front bracing

- Rear bracing

- Vertical bracing

2. Main support structure system

- Bottom longitudinal beam

- Front support beam

- Rear support beam

3. Launching device and anchor system

- Front bogie

- Rear pull-down beam

- Launching device

4. Hoisting System

- Support beam hoist

5. Formwork system

- External formwork

- Internal formwork

- 0# Block formwork

6. Working platform system

- Upper working platform

- Lower working platform

- Front ladder

- Rear ladder

- Protective guard

Expert at This Area

Our service.

- Tender stage quotation preparation

- Rebuilt design regarding existing equipments delivered by us, for use in different conditions of the original

Send a Message

Your contact to ohc.

Address: 195, E. 4th Ring Rd Middle, Chaoyang District, Beijing, 100124, China

Phone: +86 13941265037

Thank you for your interest in OHC Formwork. To help us promptly meet your request, please Send a Message, Email, or Call Us, Follow Us.

Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. When you join you get additional benefits.

Confirm Password *

First Name *

Last Name *

Country Select a country… Åland Islands Afghanistan Albania Algeria Andorra Angola Anguilla Antarctica Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belau Belgium Belize Benin Bermuda Bhutan Bolivia Bonaire, Saint Eustatius and Saba Bosnia and Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory British Virgin Islands Brunei Bulgaria Burkina Faso Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos (Keeling) Islands Colombia Comoros Congo (Brazzaville) Congo (Kinshasa) Cook Islands Costa Rica Croatia Cuba CuraÇao Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Ethiopia Falkland Islands Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guatemala Guernsey Guinea Guinea-Bissau Guyana Haiti Heard Island and McDonald Islands Honduras Hong Kong Hungary Iceland India Indonesia Iran Iraq Isle of Man Israel Italy Ivory Coast Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macao S.A.R., China Macedonia Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia Moldova Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar Namibia Nauru Nepal Netherlands Netherlands Antilles New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island North Korea Norway Oman Pakistan Palestinian Territory Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Poland Portugal Qatar Republic of Ireland Reunion Romania Russia Rwanda São Tomé and Príncipe Saint Barthélemy Saint Helena Saint Kitts and Nevis Saint Lucia Saint Martin (Dutch part) Saint Martin (French part) Saint Pierre and Miquelon Saint Vincent and the Grenadines San Marino Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Georgia/Sandwich Islands South Korea South Sudan Spain Sri Lanka Sudan Suriname Svalbard and Jan Mayen Swaziland Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tokelau Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Turks and Caicos Islands Tuvalu Uganda Ukraine United Arab Emirates United Kingdom (UK) United States (US) Uruguay Uzbekistan Vanuatu Vatican Venezuela Vietnam Wallis and Futuna Western Sahara Western Samoa Yemen Zambia Zimbabwe

By registering, you agree to the Terms of Service and Privacy Policy . *

Log in to TheConstructor to ask questions, answer people’s questions, write articles & connect with other people. When you join you get additional benefits.

Join for free or log in to continue reading...

Username or email *

Forgot Password

Lost your password? Please enter your email address. You will receive a link and will create a new password via email.

Sorry, you do not have permission to ask a question, You must log in to ask a question. Join now!

The Constructor

Balanced cantilever method of bridge construction.

Do you need to remove the ads? Join now!

🕑 Reading time: 1 minute

What is balanced Cantilever method of Bridge Construction?

Fig.1: details of cantilever method of bridge construction (Cast in situ segment)

Fig.2: details of cantilever method of bridge construction (precast segments)

Procedure for balanced cantilever method of cast-in-situ bridge Construction

Fig.3: construction of lower infrastructure of bridge

Fig.4: Positioning of special formwork

Fig.5: Soffit, web, and Deck shuttering

Fig.6: shuttering soffit, web, and decks

Fig.7: concrete placement

Fig.8: Concrete placement

Fig.9: bridge construction progression

Fig.10: Construction of closer section of the bridge

Sequence of balanced cantilever method of precast bridge construction

Fig.11: Pier construction

Fig.12: lifting frame

Fig.13: End span segment o false work

Casting of precast segments

- Short line method: In this rate of segment production is slow. Three or four segments cast at a time.

- Long line method: In this rate of segment production is fast. Segments equal to one span cast at a time.

Fig.14: Short line segment casting

Fig.15: Long line segment casting

Cast-in-Place Segments Vs precast segments

- Cast-in-place construction proves to be very beneficial when large, considerably heavy segments are required to be constructed. So, instead of handling the segments, only materials have to be transported thus influencing the type and size of required equipment.

- Alignment variations and corrections are more easily accommodated in cast-in-place construction; but more corrections will probably be necessary.The increase in alignment corrections for cast-in-place construction compared to precast construction relates directly to the age of the concrete when loaded. By and large, the concrete is much younger when loaded in cast-in-place construction.

Madeh Izat Hamakareem

Related posts.

16 Types of Pipelines and their Construction Method

Design of Steel Tanks

- Construction Calculator: Simplified Construction Cost Calculator

- Members Login

What Is Form Traveler In Construction?

- Building & Construction

A form traveller is a type of travelling formwork system used in bridge construction. It enables the repeated construction of structural elements and is typically used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges.

Form travellers are supported by the part of the structure already built, and can be overhead or underslung

Form traveller is a system used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. It is lightweight, versatile, easy to assemble and operate, rolling forward on rails or rollers, and supports the weight of the construction elements including formwork, traveler, reinforcement and uncured concrete.

The form traveller system is designed to be highly stable and rigid so that it does not move significantly under the weight of the concrete as it is poured or during curing. It also has features such as being portable and cost effective.

The Standard form traveller is intended to be used for bridge construction and has a maximum segment length of 5 meters. The load capacities for concrete and formwork can range from 250 to 400 tonnes. The weight of the steel used in the form traveller depends on the specific cross-section of the bridge, typically ranging from 25 to 65 tonnes.

It is possible to modify the Standard form traveller to fit almost any cross-section and adjust it during use to accommodate changes in segment length, section height, web thickness, and deck width.

What Is Form Traveler Used For?

Form travellers are used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. They are lightweight, versatile, easy to assemble and operate, rolling forward on rails or rollers, and offer significant cost savings over traditional methods.

Form travellers are preferred for building spans over deep valleys, waterways, and roads where access from the ground is a challenge and the number of piers is limited.

The main advantage of form travellers over other construction methods is that they allow for longer and wider spans to be built with less material than traditional methods.

Form travellers come in two types: overhead form travelers which are suspended underneath the bridge structure already erected, and under-slung form travelers which are mounted on top of the structure already erected.

Is Form Traveler Used For Construction Of Superstructure?

Form travelers are commonly used for the construction of cantilever segmental bridges, as they provide a convenient and efficient means to build superstructures.

These form travelers give shape to the segment, support the weight of the newly cast concrete until it has gained enough strength to be post-tensioned to the previous cantilever segments, and transfer the segment weight to the already existing superstructure.

Form travelers can also be used in certain circumstances for other types of bridge structures (such as truss or arch bridges), depending on the specific design requirements.

Form Traveller Installation

Installation of form traveller involves assembling the equipment on the ground and lifting segments by crane to their starting points on a specific bridge pier.

Form travellers come in two main types: overhead and underslung, with both being designed for free cantilever construction of pre-stressed girder and cable–stayed concrete bridges.

Structural analysis is used to improve the performance and alignment of bridges, as well as ensure that the formwork does not move significantly under the weight of the concrete during pouring or curing.

Form Traveller Components

Form traveler components consist of a main frame, walking and anchoring device, bottom mould frame, side mould frame, inner mould frame, front lifting device and rear lifting device which are important for the smooth functioning of form travelers.

The main frame provides stability to the whole assembly while the walking and anchoring devices assist in its movement. The mould frames form an enclosure for supporting the form structure pieces and the lifting devices on both ends help in moving them between different levels.

Related Posts

What is an electroless plating.

What Is An Electroless Plating? Electroless plating, also known as chemical plating or autocatalytic plating, is a method of creating a metal coating on a variety of materials through the use of a chemical bath that reduces metal cations. This process differs from electroplating, in which an electric current is used to create the metal […]

What Is Exterior Insulated Finishing System?

What Is Exterior Insulated Finishing System? Exterior Insulated Finishing System (EIFS) is a non-load bearing building cladding system that provides exterior walls with an insulated, water-resistant, finished surface in an integrated composite material system. EIFS has been in use since the 1960s in North America, and was first used on masonry buildings. Since the 1990s, […]

What Is A Facing Tool In Metalwork?

What Is A Facing Tool In Metalwork? A facing tool is an important tool in metalwork that is mounted into a tool holder and placed onto the carriage of the lathe, allowing the user to cut away material from the outer surface of a rotating piece. Facing tools feed perpendicularly across a part’s rotational axis […]

- COMPANY OVERVIEW

- DESIGN CAPACITY

- MANUFACTURING

- OUR MISSION

- onsite services

- equipment leasing

Form Traveller

SDI FT is a cost – effective and reliable solution!

Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable – stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths. Our formwork can be supplied with wooden, steel or plastic sheeting, which can be recycled.

Home/ About / Equipment / Services / Projects / Contacts

- COMPANY OVERVIEW

- DESIGN CAPACITY

- MANUFACTURING

- OUR MISSION

- Equipment Launching Equipment for Precast Bridges Precast Full Span Launcher Precast Segment Launching Gantries Beam Launchers Segment Lifter Launching Equipment for Cast In Situ Bridges Form Traveller Movable Scaffolding System Heavy Lifting and Transportation Equipment Gantry Crane Straddle Carrier Transporter SEGMENT CARRIER Shipyard Lifting & Transportation Equipment Shipyard and Port - Handling & Transportation Equipment

- onsite services

- equipment leasing

- Precast Full Span Launcher

- Precast Segment Launching Gantries

- Beam Launchers

- Segment Lifter

Form Traveller

- Movable Scaffolding System

- Gantry Crane

- Straddle Carrier

- Transporter

- SEGMENT CARRIER

- Shipyard and Port - Handling & Transportation Equipment

SDI FT is a cost – effective and reliable solution!

Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable – stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths. Our formwork can be supplied with wooden, steel or plastic sheeting, which can be recycled.

Home / About / Equipment / Services / Projects / Contacts

You are currently visiting the International Doka website

- Organization

- Project management

- Sustainability

- Code of Conduct

- Report anonymously

- Procurement

- Residential & commercial high-rise construction

- Power Plants

- All references

Formwork & Solutions

- Systems & components

- Construction solutions

- All products & services

- Low Carbon Concrete in construction

Digital solutions

News & updates.

- Tradeshows & dates for your calendar

- Education meets Technology

- Careers at Doka

- Working areas

- Current job offers

- Working World

Balanced Cantilevered Bridges

Bridging wide spans with the balance beam principle

In the free cantilever method of construction the prestressed-concrete superstructure, generally boxlike in section, is cast section by section. Two cantilever arms are built in opposing directions, extending away from the pier head (or 'hammerhead' as it is often termed). In order to ensure that this 'balance beam' does not topple off the head of the bridge pier, the superstructure is connected to the pier in such a way as to remain flexurally rigid, or it is held by temporary supports or temporary piers until the through-beam supporting effect of the superstructure is established by what is known as gap closure. Even though the connection through to the pier is flexurally rigid, the two extensions have to be kept within a precisely defined maximum load delta. Consequently, there can be no more than a minor difference in the lengths and weights of the two cantilever arms.

Highlights:

- spans up to 300 m can be bridged efficiently with conventional cantilevered construction

- used for wide spans (valley, river, sea, nature conservation area, etc.)

- nothing to obstruct traffic (road, rail, shipping) underneath the structure

- the pier head is the starting segment for the pair of cantilever forming travellers and it also absorbs the enormous support moments and loads deltas during construction

- generally a one-week cycle for casting and prestressing each pair of segments

- defined work cycle: process-oriented completion of the sections for high efficiency and quality

- starting segment for the cantilever forming travellers

- constructed using load-bearing tower, timberbeam formwork and framed formwork systems

- extensive safety features for safe working conditions

Gap closure

The closing cycle has to go smoothly, but it is also very important to plan the disassembly or retraction of the cantilever forming travellers.

Optimised interface between Doka and structural engineer

As regards planning the anchor holes for the cantilever forming traveller, close coordination with the structural engineers is essential in order to avoid collisions with the bridge's tensioning-cable system. This method of construction involves relatively large deformations, so super-elevation has to be calculated accurately and conditions checked and adapted after every pouring operation. Doka supplies the structural engineer with the data on system deformations for each cycle.

Expressway R3 Tvrdošín

Bridge Dumanja Jaruga

Artvin Şilenkar Viaduct

Başarköy Viaduct

RA217 Nawaseeb Road

Ampliación doble calzada

D1 Prešov SO203 bridge

Eyiste Viaduct

Varoddbrua 2

M2-3 Ostroda Bridge

Ticino Bridge

Motorway Bridge SO 223

Aberdeen Western Peripheral Route (AWPR)

Lahntal Bridge

Bridge near Teror

Bridge over the River Elbe

Tisza Bridge

Danube bridge at Traismauer

Inn-bridge Ehring

Corridor Vc, bridges at Studenčica and Trebižat

Arad Bypass

Formwork Systems & Services

Get in touch.

The international experience of Doka gives you pooled, concentrated knowledge for a successful project. Your contact person will help you find the best individual solution, to make your project's 'bottom line' a success, too. In short: expert specialised formwork planning with lasting benefits for your bridge construction project.

Formwork & Solutions

News & updates, thank you for your interest - balanced cantilevered bridge., please, fill in the form below to receive more information on this topic and access it conveniently from your email later..

All listed fields are required. By using our site, necessary cookies are set on your device for the execution of the service. Find out more in our data privacy policy https://www.doka.com/data-privacy .

Thank you very much for your interest - Balanced Cantilevered Bridge.

A link with further information has been sent to the provided e-mail address..

You can now switch back to the QR code reader to request information on other topics. You have the option to save your contact details to be automatically used for your next request.

Consent to cookies & data transfer to the United States of America

We request your consent

1) to the use of cookies

2) to the transfer to the united states of america of data obtained through the cookies.

1) Use of cookies We, Doka GmbH, use cookies and third-party applications. This helps us ensure optimum performance of our website, in particular

- to continuously improve the functionality of our website,

- to facilitate the experience of using the Doka Online Shop, or

- to place advertising suitable for you as user on certain platforms.

Technically necessary cookies (essential) are required for the proper functioning of the website. If you do not agree with the processing of your data by setting technically necessary cookies, you will not be able to access the website. See also: "Advanced cookie settings".

See our Data Privacy Statement for more information about our cookies. We also offer you the possibility of selecting your cookies (advanced cookie settings).

2) Data transfer to the United States of America Some of our partners are entities established in the United States of America. We transfer your personal data manually or via an interface to these partners in the United States of America.

We would like to inform you that the ruling of 16 July 2020 (Court of Justice of the European Union judgement in case C-311/18, “Schrems II”) invalidates the EU - U.S. Privacy Shield decision that permitted a transfer of personal data to the United States of America. In consequence, as a third country the United States of America does not offer an adequate level of data protection.

For you as user, the risk that the transfer of personal data to an entity established in the United States of America is in particular that your data are subject to access by the United States authorities for monitoring and surveillance purposes and that to a large extent you are without effective administrative and judicial right of redress against such action by the United States authorities.

Personal data that we transfer to the United States of America are in particular IP addresses (Internet Protocol addresses).

We co-operate via various applications with the following recipients:

- Facebook LLC

- MaxMind Inc.

- Microsoft Corporation

- Monotype Imaging Holdings Inc.

- Rocket Science Group LLC

- Sketchfab Inc.

- The Trade Desk, Inc.

- YouTube LLC

We require your explicit consent to continue sending your personal data to these providers.

You can revoke your consent with effect for the future at any time, by accessing the cookie settings on the website.

Do you consent to the use of cookies and the transfer of your personal data to the United States of America?

Advanced cookie settings

You can amend your cookie settings at any time using the cookie settings link in the page footer. Please refer to our extensive privacy statement for more information.

8618513399356

- About Us Company Profile Production Patents Certificates Awards

- Products Form Traveler Segmental Box Girder Formwork T/I/U Girder Formwork Pier Formwork Tunnel Lining Trolley

- Services R&D Capability IUR Cooperation Design Support On-site Services

Project Cases Form Traveler Cases Segmental Box Girder Cases T/I/U Girder Formwork Cases Pier Formwork Cases Tunnel Lining Trolley Cases

- Cooperation Cooperation Modes Rental Business Agency

- News & Blogs News Blogs

- Contact Us Contact Information Catalog and Brochure Technical Documentation Video View

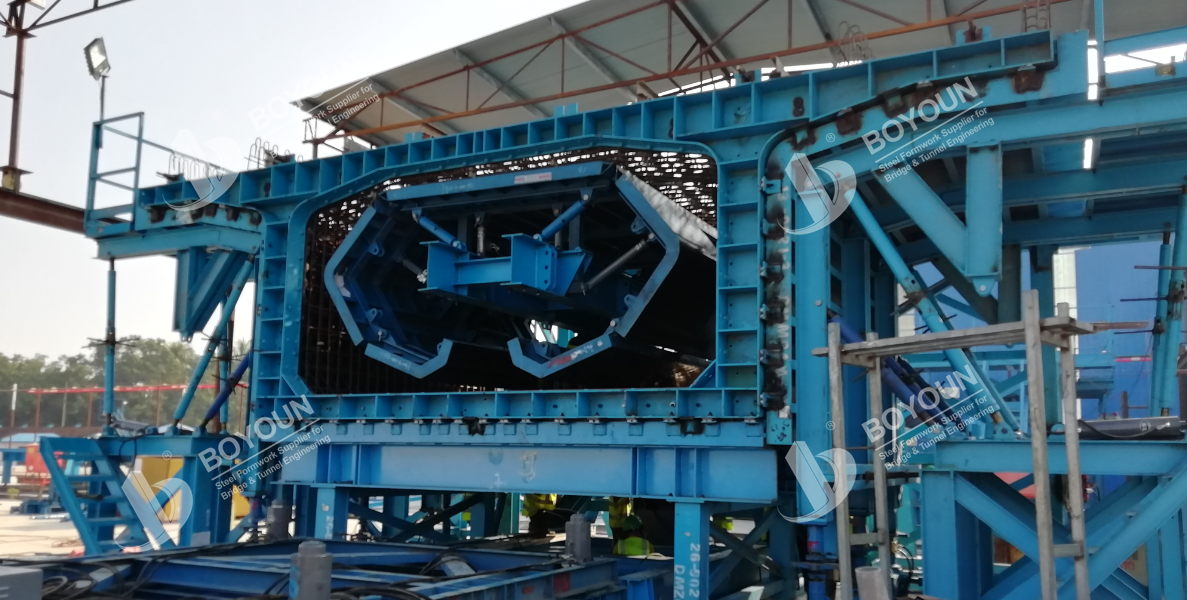

About Boyoun

Boyoun Group was founded in Beijing in 2005. Now as one leading National High-Tech enterprise group that specialized in the research and development of infrastructure construction materials, and providing R&D and manufacturing , leasing, re-purchasing and re-manufacturing, resource sharing and platform services.

The company headquarter is in Binzhou Industrial Zone, Shandong Province. with 400 employees and annual output of 50,000 tons of infrastructure equipment (more than 5,000 sets), 6,0000 tons of self-owned leased

materials, and 100,000 tons of operation and maintenance equipment. Rental material can be achieved in major areas of the Chinawithin a 15-day transition in place, and it can help customers save 30%-50% of the dominant cost directly.

Bulit On Trust

- Cooperation

Products All products

Single box single cell segmental box girder formwork.

Steel Formwork For Precast Box Girder Construction For Road, Expressway and LRT.

Precast U Girder Formwork

Steel Formwork For Precast U-Shape Girders for High-speed Rail and LRT Construction.

Precast T Girder Formwork

Steel Formwork For Precast T-Shape Girder Construction for Road and Expressway.

Tunnel Lining Trolley

Steel Tunnel Formwork for Road, Expressway, Subway and High-speed Rail Construction.

Single Box Single Cell Cantilever Form Traveler

Single Box Double Cells Cantilever Form Traveler

Technical Services

Technology innovation leads the future..

- R&D Capability

- IUR Cooperation

- Design Support

- On-site Services

Our Latest News

Coordinate online and offline practice to build a comprehensive network of epidemic prevention and control

Intellectual Property Innovation Conference of 2019

Introduction to cantilevered installation of box girder segments on viaducts.

2 Methods for Precast Segmental Box Girder

How to Select Bridge Types in Different Regions

We focus on turn-key solutions and types of formwork for Bridge and Viaduct Construction at home and abroad since 2006.

Quick Links

- Project Cases

- News & Blogs

Get In Touch

International Department: Room 2211-2212, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

IMAGES

VIDEO

COMMENTS

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workflow. The perfect design match between the CFT's shoring structure and the formwork, its high standard of safety and its optimised workplace-ergonomic design together ensure that work can progress swiftly ...

fully railed-in working platforms on all levels. integrated ladders, complete with ladder-cages. the safety feature which self-locks the CFT while it is being advanced on sliding plates. With the newly developed cantilever forming traveler, the 20 ft. long deck segments of the Viaducto de Teror are being cast in a weekly cycle.

The form traveller system is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide. The system is lightweight, versatile, easy to assem...

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workflow. The...

If you are looking for balanced cantilever bridge construction methods for form travelers, then this video is for you! In this video, we walk you through the...

Form Traveller Bridge Construction. Form Traveller Specifics. Form travellers can be employed during cantilevered concrete girder construction when a bridge pier can be used as a starting point. Opposite directions of span construction are facilitated by using the top of a pier as the initial anchor point for two separate form travellers (each pair of form travellers operates as a unit).

The Form Traveller is a temporary support structure supporting the weigh of the bridge and viaduct deck segments cast in situ built by the cantilever method from the pier head to the center of the span. 01. Safe, Typical, Adjustable ...

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workflow. The perfect design match between the CFT's shoring structure and the formwork, its high standard of safety and its optimised workplace-ergonomic design together ensure that work can progress swiftly and safely.

Cantilever casting is commonly used in building concrete bridges. As an important temporary structure in cantilever casting, the form traveler can be divided into the rear fulcrum form traveler and the front fulcrum one based on the stress mode. 1-5 There are triangles, and diamonds form travelers, which are applied to the cantilever casting construction of concrete bridges.

The balanced cantilever method of bridge construction used for bridges with few spans ranging from 50 to 250m. The bridge can be either cast-in-place or precast. ... The segment production rate for form travelers is usually one segment every 5 days per traveler. Cast-in-situ segments range between 3m to 5m in length with formwork moving in ...

A form traveler used in bridge construction has a great influence on the safety of the performance and alignment of bridges. As a cantilever casting segment of a bridge becomes longer and heavier ...

A form traveller is a type of travelling formwork system used in bridge construction. It enables the repeated construction of structural elements and is typically used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. Form travellers are supported by the part of the structure already built, and can ...

cantilever casting, the form traveler can be divided into the rear fulcrum form traveler and the front fulcrum one based on the stress mode.1-5 There are triangles, and dia-monds form travelers, which are applied to the cantilever casting construction of con crete bridges. The front form traveler is more applied to the cantilever casting ...

Form Traveller. SDI FT is a cost - effective and reliable solution! Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable - stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workfl ow. The perfect design match between the CFT's shoring structure and the formwork, its high standard of safety and its optimised workplace-ergonomic design together ensure that work can progress swiftly and safely.

The form traveler formwork system is a non-standard mechanical equipment used for continuous cantilever construction. Advantages of Boyoun form traveler:Cantilever beam construction equipment champion; professional design team and after-sales team; leading industry standardization design since 2013, involved in formulating industry norms; delivering more than 1,000+ form traveler cases; the ...

The form traveller system is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide. The system is lightweight, versatile, easy to assem...

Product Description. Cantilever form traveler with main span below 150 meters refers to the form traveler applicable to bridges with main span below 150 meters. Scope of application:The cantilever form traveler with main span below 150 meters is suitable for the construction of small and medium-span bridges, including highway bridges, railroad ...

Balance Cantilever Method Form Traveller. Working Slope: 3%. Maximum weight: 336 Ton. Own weight: 122 Ton. Year: 2010. Our Balance Cantilever Method Form Traveller is suitable for different types of bridge construction, it is not affected by the terrain, and it is relatively easy to operate. Buyers are highly appreciative of the flexibility and ...

Form Traveller. SDI FT is a cost - effective and reliable solution! Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable - stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

In short: expert specialised formwork planning with lasting benefits for your bridge construction project. František Madleňák Business Development Manager [email protected] +43 664 88384341. Dominik Will Business Development Manager [email protected] +43 664 7835 9249. The bridge between knowledge and experience - our expertise ...

Boyoun Heavy Industries Co., Ltd specializes in supplying a wide range types of formwork for bridge, viaduct and tunnel engineering. The headquarter and main factory are located in Binzhou city of Shandong province, with International Department located in Beijing. Main products cover: Precast Box Girder Mould, Cantilever Form Traveller, I/T/U Girder Formwork, Tunnel Lining Trolley, Pier ...

The form traveller system is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide. The system is lightweight, versatile, easy to assem...