- Sustainable

- Energy Economy

- Energy Services

What is Round Trip Efficiency?

Energy storage systems function by taking in electricity, storing it, and subsequently returning it to the grid. The round trip efficiency (RTE), also known as AC/AC efficiency, refers to the ratio between the energy supplied to the storage system (measured in MWh) and the energy retrieved from it (also measured in MWh). This efficiency is expressed as a percentage (%).

The round trip efficiency is a crucial factor in determining the effectiveness of storage technology. A higher RTE indicates that there is less energy loss during the storage process, resulting in a more efficient overall system. Grid systems engineers strive for energy storage systems to achieve an 80% RTE whenever feasible, as it signifies a desirable level of efficiency and minimizes energy losses.

What Factors Can Affect the Round Trip Efficiency of an Energy Storage System?

The RTE of an energy storage system can be influenced by various factors, including:

1. Technology: Different storage technologies have varying round-trip efficiencies. For example, hydro storage typically ranges from 65% in older installations to 75-80% in modern deployments, while flywheels have efficiencies of about 80% to 90%. Some battery technologies can have round-trip efficiencies ranging from 75% to 90%.

2. Storage duration: Some technologies may experience leakage or energy loss over long-term storage, which can affect round-trip efficiency. It is important to consider the specific characteristics and limitations of the storage technology when evaluating its efficiency.

3. Age and condition of the system: Older storage systems may have lower round-trip efficiencies compared to newer ones. Factors such as wear and tear, component degradation, and maintenance practices can impact the overall efficiency of the system.

4. Charging and discharging rates: The speed at which energy is charged into and discharged from the storage system can affect its efficiency. Certain technologies may have lower efficiencies at high charging or discharging rates.

5. System design and control: The design and control strategies implemented in the energy storage system can influence its round-trip efficiency. Optimal system design, efficient power electronics, and effective control algorithms can improve the overall efficiency of the system.

6. Temperature: Temperature can have an impact on the performance and efficiency of energy storage systems. Extreme temperatures can affect the efficiency of certain storage technologies, such as batteries, leading to lower round-trip efficiencies.

Considering these factors is crucial when evaluating the round-trip efficiency of an energy storage system, as they can significantly affect its performance and effectiveness in storing and retrieving energy.

Must Read: What is Power Conversion Efficiency?

Elliot is a passionate environmentalist and blogger who has dedicated his life to spreading awareness about conservation, green energy, and renewable energy. With a background in environmental science, he has a deep understanding of the issues facing our planet and is committed to educating others on how they can make a difference.

Related Posts

What is Heating Seasonal Performance Factor (HSPF)?

What is Annual Fuel Utilization Efficiency (AFUE)?

What is Grid Parity?

Save my name, email, and website in this browser for the next time I comment.

Type above and press Enter to search. Press Esc to cancel.

Advertisement

Energy Storage with Highly-Efficient Electrolysis and Fuel Cells: Experimental Evaluation of Bifunctional Catalyst Structures

- Original Paper

- Open access

- Published: 13 January 2023

- Volume 66 , pages 546–559, ( 2023 )

Cite this article

You have full access to this open access article

- Enno Wagner ORCID: orcid.org/0000-0003-3170-8020 1 ,

- Erik Delp 1 &

- Rakesh Mishra 2

2904 Accesses

4 Altmetric

Explore all metrics

With the roll-out of renewable energies, highly-efficient storage systems are needed to be developed to enable sustainable use of these technologies. For short duration lithium-ion batteries provide the best performance, with storage efficiencies between 70 and 95%. Hydrogen based technologies can be developed as an attractive storage option for longer storage durations. But, common polymer electrolyte membrane (PEM) electrolyzers and fuel cells have round-trip system efficiencies of only 30–40%, and platinum and rare iridium catalysts are needed. Thus, it is a major challenge to increase the energy conversion efficiency of electrolyzers and fuel cells significantly, and at the same time to use non-precious catalysts. The present work experimentally examines the usefulness of a bifunctional NiC catalyst in two different assemblies: an alkaline fuel cell (AFC) with electrolyte gap and gas diffusion electrodes and an alkaline membrane electrolyzer (AEL). The performance characteristics of the novel system are compared with a reversible PEM fuel cell. While the AEL reaches acceptable power densities, the PEM based system still performs better than the proposed system. The AFC with an electrolyte gap provides remarkable results as it shows vanishingly small overvoltage during electrolysis at temperatures around 90 °C and current density of 100 mA cm −2 : an electrolyzer efficiency of about 100% could be achieved for the single cell. The round-trip efficiency was also very high: 65% were realized with 50 mA cm −2 . While the current density must be improved, this is a promising result for designing highly-efficient energy storage systems based on alkaline fuel cells.

Similar content being viewed by others

PEM water electrolysis for hydrogen production: fundamentals, advances, and prospects

A Review of Rechargeable Zinc–Air Batteries: Recent Progress and Future Perspectives

High-Entropy Strategy for Electrochemical Energy Storage Materials

Avoid common mistakes on your manuscript.

1 Introduction

The climate Change and its consequences are the most important problems that the civilization faces today. The sixth report of the Inter-governmental Panel on Climate Change (IPCC) has now provided a clear correlation between greenhouse gas emissions from human activities and rapid climate change. To avoid dramatic ecological and economic consequences due to drought disasters, storms and heavy rain, the global warming must be limited to 1.5 °C [ 1 ]. To achieve this, the global energy infrastructure needs to change to a CO 2 -neutral energy infrastructure. This is a major challenge that needs to be addressed urgently through world-wide collaboration and concerted research efforts.

While the infrastructure of concentrated fossil energy carriers like oil and natural gas is a uni-directional distribution system, which is characterized by continues supply and high profits, the use of renewable energies is quite different. Wind, water and solar power require large areas to collect the energy and daily and seasonal fluctuations lead to a need of an integrated sophisticated storage systems. In future, it is expected that nearly all the stake holders of the energy network will be both—consumers and producers of renewable energy. Thus, the existing models of energy economy will undergo substantial changes. Stefan Rohrmoser from the Eaton network company predicts: Rather than the tree structure, we need a flexible cellular structure that resembles an actual web, with multiple interconnections and pathways for energy to travel [ 2 ].

Since photovoltaic systems produce today cheaper energy than the conventional power plants, these systems are expected to be installed on a large scale—from single houses to huge areas on industrial buildings or on agriculture land. To compensate the daily fluctuations and to meet supply and demand gap, the first mean of choice for energy storage are lithium-ion batteries, since they have a high degree of efficiency of above 90% [ 3 ]. In [ 4 ] a storage efficiency around 95% is reported. Efficiencies of Lithium-Ion Batteries in residential homes are reported to be in the range of 82–89% [ 5 ]. To meet world-wide energy storage requirements, this option would mean, use of huge amount of raw materials like lithium, cobalt and rare-earth elements. Also, geo-political situation in many of the producing countries of these metals are quite challenging. Against this background, alternatives for storing electricity from renewable resources need to be developed, especially when high capacities for long-term storage are needed. In an actual study from the Fraunhofer Institute of Solar Energy Systems ISE in Freiburg, Germany, the total greenhouse gas emissions over the entire lifecycle (including, production, use and disposal) of lithium-ion batteries are compared with fuel cell systems, considering also the origin of all the consumed energy [ 6 ]: with storage capacities above 60 kWh, fuel cell systems show a lower greenhouse gas food print than batteries.

During the last decades, especially the PEM technology with polymer electrolyte membranes has been developed to be used in various technical applications and it has provided reliable operation stability. In the automotive industry, PEM fuel cells are currently being developed with current densities between 2 and 3 A cm −2 [ 7 ]. The results of different PEM fuel cells are presented in [ 8 ] with current densities around 1.5 A cm −2 at usable voltages of around 0.6 V. The efficiencies of these cells are in the range of 40–50%.

During energy transition, green hydrogen is a beacon of hope for the heavy industry, as it is assumed that it will be used to drive trucks and help to decarbonize industrial processes like the steel and glass production [ 9 ]. Therefore, huge amounts of this renewable gas must be produced, preferentially close to large wind farms at the coast. Industrial companies are now developing high-power electrolyzers, also based on the PEM technology for this purpose. In [ 10 ] improved polymer electrolyte membrane water electrolysis has been shown to have very high current densities up to 5 A cm −2 while the efficiency is around 65%. This is indeed a great success in bringing the technology to an industrial scale of the megawatt range. On the other hand, the PEM electrolysis technology is still not very cost-effective. Especially at the oxygen side a high corrosive potential prevails, allowing only noble platinum and iridium catalyst to be used. The conductor plates must be milled from titanium which results in very high production costs. Furthermore, if the entire energy path of green hydrogen is considered, including electrolysis, auxiliary devices, gas compression, transportation and reconversion into electricity, the round-trip efficiency is only about 30%. While the power density can be generally increased by using thinner membranes, the efficiency of acid polymer electrolyte membranes cannot be increased furthermore due to electrochemical limits. Thus, alternatives for high-efficient energy conversion with hydrogen need to be explored.

Comparing all types of fuels cells, alkaline electrolysis and fuel cells show the highest efficiencies of all. Therefore, the alkaline technology should be discussed in detail as it is the main topic of the present work. It is in this context, that F.T. Bacon should be mentioned, a pioneer who spend all his power and motivation for researching the alkaline technology [ 11 ]. In the 1940th Bacon and his team developed the first technical useful alkaline fuel cells with porous nickel electrodes on both sides of an electrolyte gap. After some problems with the stability of the oxygen electrode due to nickel-oxide, very good results were obtained with a lithium treatment. The sintered nickel electrode was soaked with a solution of lithium-hydroxide (LiOH) and then tempered at 700 °C for some minutes. Thus, a corrosion-resistant oxygen electrode was built which was stable in high concentrated potassium hydroxide at temperatures of about 200 °C and pressures around 40 bar. Under this high reactive condition, current densities up to 1 A cm −2 were achieved. Remarkably, a high cell voltage of 900 mV at current density of more than 300 mA cm −2 was achieved, corresponding to an efficiency of about 60% [ 11 ]. The early space operations and the Apollo missions were equipped with alkaline fuel cells based on this principle [ 12 ]. This early work of F.T. is relevant for the current work, since very high efficiencies of the alkaline technology were presented here for the first time.

Furthermore, the Siemens Company in Germany has been at the fore front of developing several alkaline fuel cell systems in 1960s. The classic design of the AFC has a small gap of about 2 mm thickness with an electrolyte flow (30 wt% potassium hydroxide as mobile electrolyte). Powder electrodes with porous nickel and silver at the oxygen side were pressed with a gas pillow from both sides on asbestos diaphragms. With temperatures of around 80 °C and gas pressures of about 2 bar these cells show quite good efficiency. At 300 mA cm −2 the cell voltage was still above 850 mV. In a different design, the potassium hydroxide (KOH) is fixed (immobile electrolyte) in a matrix structure and the electrodes also contained some platinum. With these cells at current density of 400 mA cm −2 the cell voltage showed values above 900 mV [ 13 ]. This high efficiency (around 60%) at high useful power density has never been reached with modern PEM fuel cells which typically show voltages around 700 mV (47% efficiency) at this current density. It thus underscores the potential of the alkaline technology to achieve high efficiencies.

In the last decade a significant increase in publications about alkaline membranes has been observed [ 14 ]. The main motivation seems to be able to combine the high-power density of PEM fuel cells with the high efficiency of alkaline fuel cells and with an aspired cost reduction using low-price non-platinum group catalysts. While especially polymer electrolyte electrolyzers have a high corrosive potential, only noble catalysts like platinum und ruthenium are stable during oxygen evolution reaction (OER). These catalysts are also suggested for reversible PEM fuel cells [ 15 ]. If only the fuel cell mode is considered, the noble catalysts can be supported on carbon particles, for both, the hydrogen oxidation reaction (HOR) and the oxygen reduction reaction (ORR), the catalyst loading can be reduced to less than 0.5 mg cm −2 [ 12 ] with nanoparticles loadings of 0.1 mg cm −2 are possible today [ 7 ].

In the alkaline media a wide range of catalyst use has been reported. For the hydrogen reaction Pt, Pd, RANEY-Ni, NiMo, CoNiMo and Ni 3 N have been shown to be useful catalysts. For the oxygen reaction Pt, Pd, PtRu, Ag, Co 3 O 4 , MnO 2 are typically used with considerable success. In [ 16 ] several transition metals (Mo, Co, Fe, Cu) have been suggested for the alkaline HOR process. Also use of carbon nanotubes (CNT) as support and dopants with nitrogen, sulphur and boron has been reported. In [ 17 ] several bi-functional catalysts have been investigated for the usefulness for alkaline fuel cells using rotating disc technology and cyclic voltammetry. Traditionally, silver has been found to be one of the best catalysts for the ORR in alkaline fuel cells, as published extensively [ 18 , 19 , 20 , 21 ]. In the present work a nickel-carbon catalyst showed promising suitability for the oxygen reaction.

For obtaining high current densities like PEM fuel cells, modern AEMs (anion exchange membranes) have been developed which normally have thickness in the range of 20 to 100 microns, conductivities around 100 mS cm −1 and these deliver current densities above 500 mA cm −2 [ 16 ]. Alkaline membranes were originally used for water treatment and are based on a PBI structure. They were also used in classic alkaline water electrolyzers completely dipped into liquid electrolyte. In fuel cells this is not practicable because the liquid will leak out and even partly drying may destroy the structure. Since embrittlement is a well-known problem, these membranes must always be kept humidified e.g., with 1.0 M KOH [ 16 ]. Another problem is the formation of carbonates (K 2 CO 3 ) when the cations meets the carbon-dioxide from the air. Thus, a modern type of membrane has been developed which is called anion exchange membrane (AEM). Here, the functional group is chemically bounded on the structure, while the hydroxide ions are movable—thus, comparable to a PEM. Because no free cations are available, the formation of carbonates is no longer a problem and these type of fuel cells can be operated with air. Commercial products of these AEMs are available from IONOMR (Canada), FUMATECH (Germany) and DIOXIDE MATERIALS (US) with the SUSTAINION membrane. The polymer-backbone of these membrane structures could be polyethylene, polyphenylene or poly-ether-ether-ketone (PEEK) which is very stable even at high temperature. Often, the base is also polyether-sulfone (PES or PESU) [ 22 ]. With AEMs significantly high current densities can be obtained. In [ 23 ] a power density of 1.4 W cm −2 is reported with current densities around 3.0 A cm −2 . In [ 14 ] current densities of 4.0 A cm −2 given and [ 16 ] presents current densities of even 6.0 A cm −2 . However, all these AEMs have a catalyst loading of platinum and ruthenium like conventional PEM fuel cells.

It can be concluded that AEMs are not enough stable at higher temperatures because partly drying and embrittlement can damage the membranes. This is the reason for the lack of availability of commercial fuel cells equipped with AEMs. In electrolyzers the risk is much lower since there is always liquid water at the membrane. The ENAPTER company is starting production of small modular electrolyzer devices using AEMs, but temperature level and efficiency are still relatively low. This is unfavorable since much high efficiencies can be reached with alkaline systems especially at high temperatures.

Since alkaline membranes are sensitive to high temperatures, a promising attempt is given in [ 24 ], avoiding the use of any membrane. In a small test cell, a capillary flow of electrolyte is feeding a porous structure made of a hydrophilic polyether-sulfone (PES) separator in-between two electrodes. Hydrogen and oxygen evolution can be obtained without the formation of bubbles. The results are impressing: at current densities of 500 mA cm −2 the electrolyzer cell works with a voltage of only 1.51 V, corresponding to an efficiency of about 98%.

Because of the above-mentioned shortcomings of alkaline membranes, the authors of the on-hand work are following a similar approach like [ 24 ] with the focus on highly-efficient electrochemical energy conversion in porous catalyst structures—without any membrane. Therefore, a cost-efficient alkaline fuel cell in the classic design with gas diffusion electrodes on two sides of an electrolyte gap has been developed and was presented in a previous work [ 25 ]. Here, different electrodes have been examined to provide answers to the following unanswered question: are there useful non-platinum group catalysts for designing a regenerative alkaline fuel cell? A cost-efficient bifunctional catalyst based on a mixture of RANEY-Nickel, PTFE and a stable carbon shows promising results in both, fuel cell as well as electrolyzer mode. In the present work these studies were extended while two different cell designs are compared. The overriding goal is to find an optimal configuration of catalysts, electrode structure and cell design for alkaline electrolyzers and fuel cells with highest efficiency, high power density and low-cost production potential.

2 Fundamentals

In fuel cells the chemical energy of the hydrogen is directly converted into electric energy using an electrochemical process. The maximum effectively useful energy (exergy) is given by the GIBBs free reaction enthalpy ΔG . Hereby, the bond enthalpy ΔH represents the chemical energy of the hydrogen and cannot be fully converted into electrical energy. It is diminished by a term of the absolute temperature T and the change of entropy ΔS .

When hydrogen and oxygen react to water the total number of molecules will be reduced. This is accompanied with a reduction of entropy, since the number of molecules is directly related to the entropy through the BOLZMANN constant. But, in a closed system the entropy cannot be reduced spontaneously due to the second law of thermodynamics. Thus, heat must be discharged into the environment in the same quantity as the term TΔS . This heat energy is lost and cannot be used for producing electric energy. In electrolysis mode it is the other way around: here the number of molecules will increase and with it the related entropy, while heat must be delivered into the system. If the electrochemical cell is working below the thermoneutral voltage ( E 0 = ΔG 0 /z F ) which is around 1.48 V, heat can be used to produce hydrogen. The electrical efficiency (electrical energy to hydrogen) is then above 100%.

Alkaline fuel cells and electrolyzers in the classic design are generally based on an aqueous solution of potassium hydroxide (KOH). Here, the hydroxide ions (OH − ) are responsible for the electrochemical current in-between the electrodes. In fuel cell mode (gas consumption) hydroxide ions are produced at the oxygen electrode and consumed at the hydrogen electrode. In electrolysis mode (gas production) the flow direction is reverse. The electrochemical equations are given below; they are reversible in general:

The hydrogen oxidation can be divided into three parts. First, the hydrogen must diffuse into the pore structure of the electrode and through an aqueous layer covering the catalyst surface. Second, the hydrogen is adsorbed on the metal catalyst and dissociated into water and electrons ( VOLMER-TAFEL mechanism). Third, the reaction water is desorbed into the electrolyte. The potential of the hydrogen electrode can be calculated using the NERNST equation. Useful catalysts for the hydrogen reaction are nickel , palladium and platinum . Silver and mercury are not usable since hydrogen cannot adsorb at its surface. RANEY-Nickel is made of an alloy of nickel and aluminum after the ignoble aluminum has been dissolved with high concentrated KOH at 80–100 °C. The remaining structure has a high porosity and a very high internal surface and is therefore a preferred catalyst. Problems are given by the formation of nickel oxide which hinders the hydrogen oxidation.

Generally, the oxygen reduction needs a high activation energy and high overvoltage, even at very good catalysts like silver and platinum (400 mV at 1 mA cm −2 ). The exchange current density is low, and the open-circuit voltage needs time to equilibrate [ 12 ]. In alkaline solution the reaction is faster than in acid media and costly noble catalysts can be replaced with nickel. During the oxygen reduction at first hydroperoxide is formed which is in the second step dissociated into absorbed oxygen. This unwanted reaction reduces the potential of the oxygen electrode especially at carbon electrodes to 0.22 V. Then, the actual open-circuit voltage of the fuel cell is only 1.05 V. Useful catalysts for the oxygen electrode in alkaline media are: platinum, platinum on carbon, silver, lithium threated nickel oxide and other metal oxides like RuO 2 and IrO 2 [ 12 ]. A very good catalyst called RANEY-Silver is produced in a similar way like RANEY-Nickel by dissolving aluminum from an alloy.

Accordingly, when catalysts are researched not only the chemical element or compound, but also the micro-structure of the metal catalyst must be considered. In a standard textbook of chemistry, the overvoltage of hydrogen and oxygen at different electrode materials are given with the clear result that platinized platinum shows significant lower overvoltage than blank platinum [ 26 ]. In [ 27 ] an electrode treatment for water electrolysis is presented using high-performance pulsed laser processing. Herewith, Ni–Fe catalysts could be produced based on nanosheets coated on thin nickel fibers for the creation of very high active surface area, with the result of significantly reduced overvoltage in alkaline media.

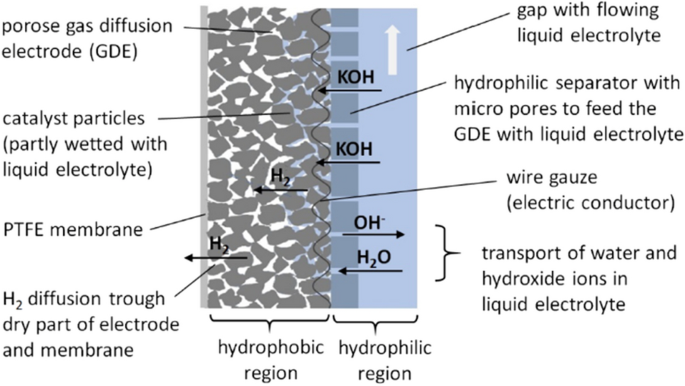

These phenomena at the nano-scale are not yet fully understood today [ 12 ]. More conceivable are the problems of mass transport in the direct surrounding of the catalyst. The reaction kinetics at the catalyst surface is quite fast in comparison to the slow process of diffusion. Since ion-transport is only possible in aqueous solutions, there must always be a thin layer liquid layer on the catalyst. Hydrogen and oxygen must dissolve into the water and then diffuse to the catalyst. This slows down the electrochemical process, especially at higher current densities. Thus, the optimal reaction place should be the thee-phase contact line where gas and the liquid meniscus meets the solid catalyst surface. Here, all reactants have the shortest way and fast supply can be ensured. Very high rates of heat and mass transfer at the three-phase contact line are also known from fundamental boiling research [ 28 ]. Consequently, it should also be the challenge of the electrode design for electrolyzers and fuel cells to create structures with a high number of these reaction placed. In the following Fig. 1 the model of a gas diffusion electrode is given visualizing this attempt.

Structural design and working principle of alkaline gas diffusion electrodes, exemplary at the hydrogen side [ 25 ]

The main part of the electrode consists of a porous structure of catalyst particles (RANEY-Nickel) which are mixed with PTFE to ensure a hydrophobic character and prevent the pores from flooding with liquid electrolyte. The frontside of the electrode (left in Fig. 1 ) is dry and in contact with the gas (here hydrogen). An additional layer of PTFE foil provides good sealing against liquid. The backside of the electrode (right in Fig. 1 ) is in contact with the liquid electrolyte flow in a gap of about 1.5 mm thickness. To prevent total flooding of the electrode it is covered with a hydrophilic separator which feeds only a limited amount of aqueous electrolyte into the catalyst structure. Consequently, a high number of thin liquid films and three phase contact lines at the catalyst surface can be assumed. It is the reason for a generally high electrochemical activity of the electrode. In practical operation the active area can be improved by adjusting the gas pressure which works against the capillary pressure of the liquid menisci in the structure. Thus, the hydrostatic equilibrium can be used to shift the phase boundary within the electrode to improve the wetting of the catalyst particles.

3 Experimental

One objective of the on-hand work is the design of a highly-efficient fuel cell system for the storage of electric energy from renewable sources. To achieve this, an experimental investigation program was developed using two different designs: a reversible alkaline fuel cell with an electrolyte gap and an alkaline membrane electrolyzer with zero-gap design. All the experimental investigations herewith were conducted in the laboratory of fuel cell technology at the FRANKFURT UNIVERSITY OF APPLIED SCIENCES (UAS). The experimental data are being compared with a reversible PEM fuel cell working in fuel cell and electrolyzer mode which was investigated in a former study of the corresponding author at the FRAUNHOFER INSTITUTE OF SOLAR ENERGY SYSTEMS (ISE) in Freiburg, Germany [ 29 ].

For the alkaline technology used in the on-hand work, a test section was developed where hydrogen and oxygen are supplied from an external electrolyzer cell, allowing an over pressure of 4 bar. With a data acquisition system, cell current and voltage, the important temperatures and the gas pressures were recorded.

The two different cell concepts were executed as given below. These designs have been carefully developed to meet the objectives of the research:

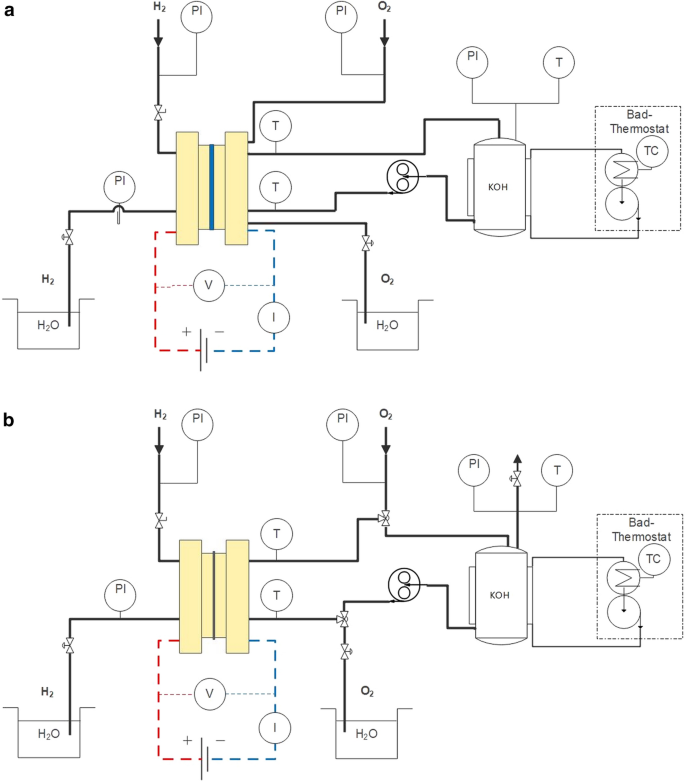

Design A: classic AFC with electrolyte gap configuration—see Fig. 3

Design B: pressure electrolyzer with zero-gap configuration—see Fig. 4

The test section testing for combined experiments in electrolyzer and full cell mode is shown in Fig. 2 . For testing the different kind of cells designs small adaptations were made. The test bench is complete build out of stainless steel, and only flour caoutchouc (FKM) sealings and tubes are used to avoid any reaction with the aggressive potassium hydroxide (KOH) even at temperatures above 100 °C [ 30 ].

Test bench for characterizing the alkaline electrolyzer and fuel cell using two different cells designs: figure a zero-gap configuration, figure b electrolyte gap configuration

In both test bench configurations, the same parts are used. The tubing is slightly different. For the zero-gap design no extra tube is needed for the O 2 transport. To use the zero-gap design in fuel cell mode, the electrolyte is removed by chancing the pump direction and feed O 2 instead of KOH into the cell. The electrolyte gap design has an additional tube for O 2 outlet. To change the operation mode of the cell with the electrolyte gap configuration no changes are needed. Switching from fuel cell to electrolyzer mode can be realized in seconds.

For all experiments a gear pump is used to circulate the electrolyte which can feed up to 5 l h −1 . The electrolyte gap design has a higher internal flow resistance leading to a reduced flow rate of 3.6 l h −1 . This value was also used for the zero-gap configuration to get comparable results. Both cell designs are mounted vertically to drive out any gas bubbles due to density differences. These could have a significant influence on the cell performance when active area is blocked by gas accumulations at the membrane or in the electrolyte gap. Therefore, the liquid is pumped from the bottom side to the top to ensure phase separation and a good wetting of the electrodes. The temperature is measured at the inlet and at the outlet of the cell with PT100 temperature sensors. The temperature sensors are fitted with T-connector directly in the electrolyte flow. Experiments with a third PT100 positioned directly in the active area of the cells has shown 5–7 K higher temperature than the inlet temperature. Consequently, the temperature information given in the subsequent diagrams have taken this internal temperature difference into account. For measuring the pressure, manometers with different scales were used. With the help of these pressure gauges and manual pressure control valves, the backpressure of the H 2 and O 2 flow in the cell could be adjusted accurate.

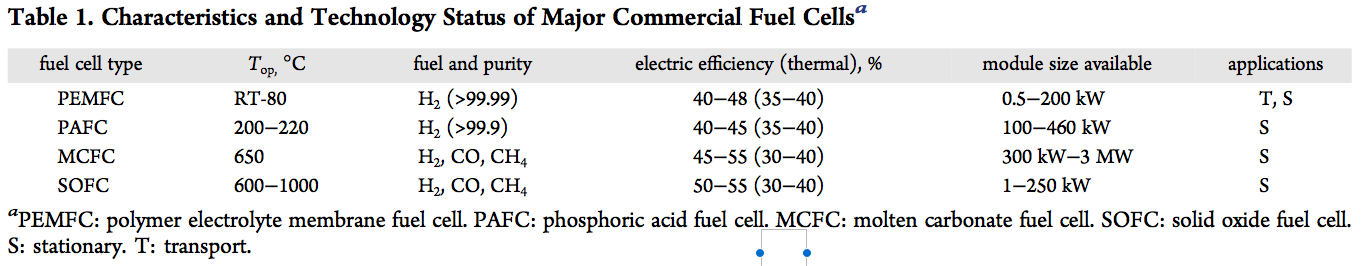

The liquid electrolyte used for all experiments was an aqueous solution of potassium hydroxide (KOH) with a concentration (by weight) in the range of 9 mol l −1 . The concentration was checked frequently with extracted KOH and titration during the different tests. The lowest value was 6 mol l −1 . For tests in fuel cell mode H 2 and pure O 2 are fed from an external electrolyzer direct to the cell without any gas treatment or humidification (Table 1 ).

The two tested alkaline cell designs are shown and described below.

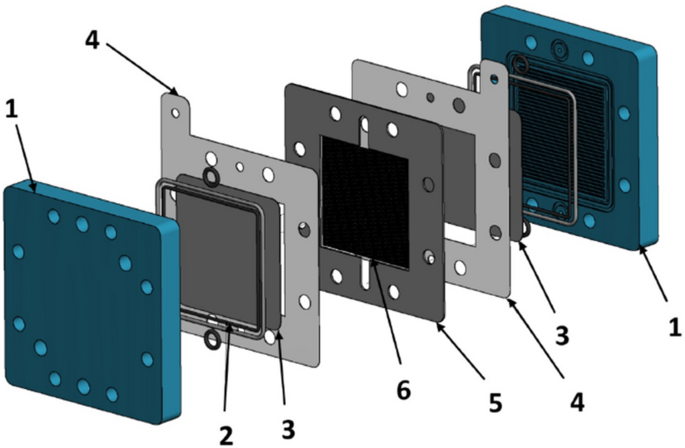

3.1 Reversible Alkaline Fuel Cell (AFC)

First, the design A is described which operates with an electrolyte gap between the electrodes. This design offers the possibility to switch between full cell and electrolyzer mode without any changes by valves or flow direction of the gas or electrolyte. The cell design has been developed at the ENNOBLE POWER Research Laboratory [ 31 ] and optimized at the FRANKFURT UAS. The design is based on traditional alkaline fuel cell of two electrodes separated by a liquid electrolyte [Rashid2015, Phillips2016]. Representative of this cell is a simple structure with cost-effective materials. No milling of metal parts is required. The assembly of the cell is given in Fig. 3 .

Structure of the reversible alkaline fuel cell (AFC) with electrolyte gap

The electrolyte gap in-between the electrodes is a crucial point of the design. The thickness of the gap is defined by a sealing frame (5) including a support structure (6). It must be very thin, to minimize ohmic resistance, also it must ensure a uniform liquid supply without holding gas bubbles inside the structure. The sealing and support structure must be chemically stable against highly concentrated KOH and thermally stable up to 130 °C. To achieve that, the used gasket was cut out of 1 mm to 1.5 mm FKM plates by laser cutting. This results in an electrolyte gap thickness < 1.5 mm. For the support structure (6) several materials and designs were observed for optimization. Meshwork of polypropylene (PP) with different thread diameters and mesh openings were investigated with positive results. (Many thanks to the PVF MESH & SCREEN TECHNOLOGY GmbH Germany, for supporting the team with samples). The end plates (1) are milled out of PP which is easy to process and has electrically insulating characteristics. Included in these endplates are two gaskets (2) and the flow fields for H 2 and O 2 . The inner gasket seals the gas channels to the electrode and outer side one seals the endplate to the nickel frames. The used electrodes (3) are pressed with the nickel mesh on the nickel sheets (4) which are used for electrical contact. The active area of this cell is 36 mm 2 which are defined by the open size of the electrodes and the extract of the nickel sheets. The electrolyte flows from the bottom to the top to ensure proper contact to the electrodes with no air bubbles [ 25 ].

3.2 Alkaline Pressure Electrolyzer (AEM)

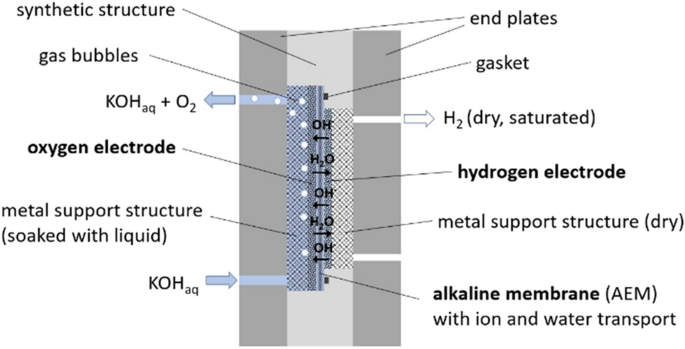

The zero-gap design for alkane electrolyzers is based on an early design from the ACTA Company and optimized by the FRANKFURT UAS where it was installed in the laboratory to test different electrodes and membranes. The design is like a PEM electrolyze for achieving high gas quality and enable the possibility to produce pre-compressed hydrogen gas. A schematic drawing is given in Fig. 4 to illustrate the zero-gap working principle (do not scale from this drawing).

Schematic design drawing of the alkaline pressure electrolyzer (AEL) with zero-gap design

Here, the core element is an alkaline membrane (AEM) or separator which ensures the transport of water and hydroxide ions (OH − ). On both sides of this membrane gas diffusion electrodes are pressed with the help of metallic support structures and massive steel endplates. The support structures were produced from differently sized stainless-steel meshworks which are welded together. The respective side facing to the electrode is polished to have a good electric contact. The support structures including electrodes and membrane are enclosed by a synthetic material structure made of polypropylene (PP) and sealed with several gaskets. This AEL cell design reduces significant the ohmic resistance of the cell in contrast to the AFC design with an electrolyte gap of about 1.5 mm thickness.

It can be taken Fig. 4 that the oxygen side of the electrolyzer is flooded with liquid electrolyte while the hydrogen side remains almost dry. This is important in terms of the mass transfer of the electrochemical process. At the hydrogen electrode, the produced gas can easily diffuse into the dry support structure rarely hindered by any liquid. At the oxygen side, gas bubbles must be formed which is an energy consuming process. On the other hand, water splitting takes place at the hydrogen electrode which means that water must diffuse through the membrane against the current of the hydroxide ions. The positive effect of a thin membrane and therewith low electrolyte resistance will be diminished by a negative effect of mass transportation. It is one target of the here presented experimental investigation to evaluate these opposing physical effects using the two different cell designs.

3.3 Electrodes

For all experiments gas diffusion electrodes developed and produced by GASKATEL Company in Germany are used. They are produced with RANEY-Nickel (Ni), polytetrafluoroethylene (PTFE) and a special carbon (C). To ensure the mechanical stability and the electrical conductivity these are integrated on a Nickel mesh. The resulting electrode is the porous structure of Ni, PTFE and Carbon with the thickness of 0.3 mm. The mixing ratio of the three substances can be varied. The hydrogen side mainly an electrode called NiH33 was used made of Ni and PTFE. For the oxygen side, carbon is added to create a bifunctional electrode called NiC. The general structural design of the electrodes is shown in Fig. 1 .

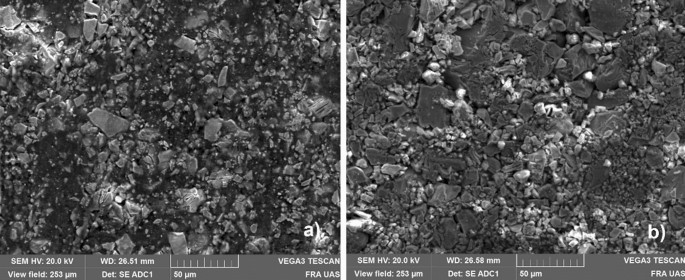

This type of gas diffusion electrode has been developed to achieve a very high number of three-phase-contact lines, where there is the region with very high activity [ 25 , 32 , 33 ]. The electrode has a hydrophobic part and a hydrophilic part. To create the optimum hydrodynamic equilibrium, the electrode could be used in different ways by integrating electrode appropriately. To support the water and KOH transport into the electrode, the electrodes could be treated with a special mixture of the electrolyte side, consisting of polybenzimidazole (PBI), N-Methyl-2-Pyrrolidon (NMP), and titanium oxide. The electrodes could also operate with a foil made of polyester-sulfone (PESU). Both are installed or applied on the Side in the electrolyte gap, where also the nickel mesh is oriented to. To avoid KOH or water in the gas channels on the opposite side of the electrode, a Teflon foil is installed here which is gas permeable but not water permeable. In the electrode itself the different gases and the water must be exchanged while diffusing and feeding liquid through the micro pores from the catalysts. The size of those micro pores depends on the mixture and size of the nickel, PTFE and carbon. The Size of the NiH33 pores are about 5–17 µm. With added carbon, those size shrinks to < 1 µm. It can be taken from scanning electron microscope (SEM) pictures in Fig. 5 .

SEM pictures of the electrode structure: NiC ( a ) and NiH33 ( b ) with 1000 × Zoom

3.4 Measurement Equipment

For all experimental designs current–voltage characteristics were recorded. Therefore, a four-quadrant electronic load (source and sink) from the HÖCHERL & HACKEL Company in Germany was used (model NL1V10C20 Standard). It allows a reliable operation in the potentiostatic mode (constant voltage) in the range from − 1 to 10 V, or in the galvanostatic mode (constant current) in a range from − 20 to + 20 A.

For measuring the impedance of the cells, the Electrochemical Workstation from the ZAHNER Company in Germany was used (model Zennium Pro). It allows a frequency range from 10 μHz to 8 MHz, with a current from − 3 to + 3 A, in a voltage range from − 15 to + 15 V.

4 Results and Discussion

To test the bifunctionality of the electrodes, initially the cell with the electrolyte gap was used for experimentation. The cell was connected to external hydrogen and oxygen supplies while the temperature of the cell was adjusted via the electrolyte flow through the electrodes. To activate the electrodes (which were oxidized in the ambient air) the cell was operated for at least 2 h while a voltage between 850 and 900 mV was achieved using the potentiostatic mode of the electronic load. After this "run-in" period, the cell was slowly stressed with the load. By increasing the voltage, oxygen and hydrogen could be produced in the cell. No other change, apart from the voltage, was necessary to switch from fuel cell mode to electrolysis mode and therewith switch the current from negative to positive flow direction. The open circuit voltage after the first electrolysis measurement settled at about 1.26 V.

As a reference, in several experiments, measurement data from a reversible PEM fuel cell are displayed. These data were recorded in an early study of the corresponding author at the FRAUNHOFER ISE in Freiburg, Germany [ 29 ]. The reference PEM cell was produced from titanium plates and used a NAFION®117 membrane. The catalyst loading at the hydrogen side was 2 mg cm −2 platinum, at the oxygen side a 1:1 mixture of platinum and iridium with also 2 mg cm −2 in total was used. Although todays PEM fuel cells applications are working with much smaller catalyst loadings and with thinner membranes, the used NAFION®117 membrane is still a standard in the fuel cell research and so still present acceptable values for comparing the general differences between acid and alkaline electrolytes.

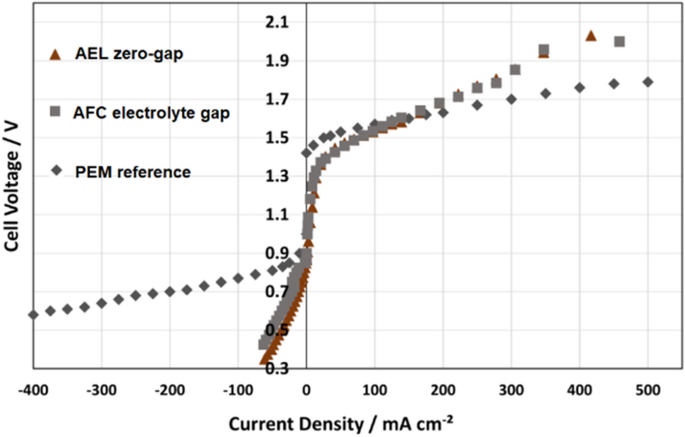

In Fig. 6 the bifunctional (reversible) behavior of AFC with electrolyte gap and with zero-gap design are compared with the PEM reference. It is obvious that especially in fuel cell mode (negative current) the PEM reference cell shows a much better behavior over a wide range, while the AFC presents only very low current densities. In electrolysis mode, the AFC is more efficient than the PEM reference for up current densities of about 100 mA cm −2 . At higher current densities the PEM reference also shows a better performance. However, it must be mentioned that the AFC works with a low-cost carbon catalyst, while the PEM reference used a high load of costly platinum and iridium catalyst.

Current–voltage characteristics of three different reversible fuel cells over the full operation range. PEM reference with data from [ 29 ]

The alkaline cell with zero-gap design presents no stable behavior in fuel cell mode. This is since the metal support structures were especially optimized for the electrolyzer mode. In fuel cell operation they soak to much liquid into the pores which blocks the gas supply of the electrode. This problem was also observed using the reversible PEM fuel cell with gas diffusion layers produced from titanium foam. Stable operation in fuel cell mode was only possible with conventional hydrophobic carbon fiber layers. Finally, it is a general problem for reversible fuel cells with zero-gap design (membrane technology). The AFC with electrolyte gap has no problem with this since the gas diffusion electrodes works almost perfect in both directions.

4.1 Electrolysis Mode

The electrolysis mode is examined in more detail below. Therefore, an alkaline membrane FAAM20 from the FUMATECH Company in Germany was installed using the zero-gap design. In AFC with electrolyte gap there was no membrane at all, but just thin layer of a hydrophilic mixtures (PBI, NMP and titanium oxide) was brushed at the liquid side of the electrodes. This protects the electrodes from flooding and shows very low resistance for the ion flow.

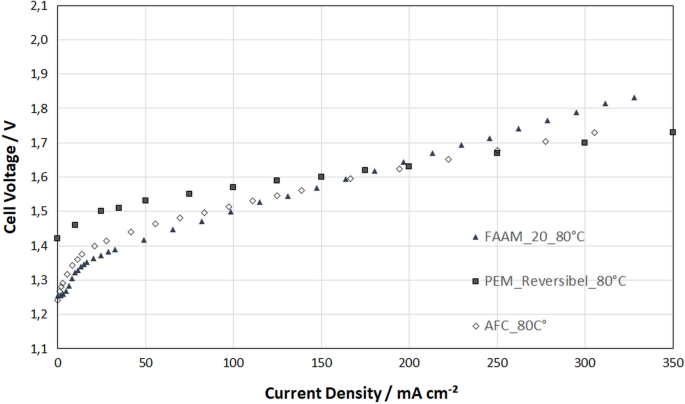

In Fig. 7 the different electrolyte and membrane assemblies are compared. One could assume that the alkaline membrane with a thickness of only 20 micron has the lowest resistance and consequently shows the best performance. But, as can be seen in Fig. 7 the AFC with a 1.5 mm thick electrolyte gap shows the best performance of all: especially at low current densities of about 50 mA cm −2 the AFC shows much smaller overvoltage than the PEM. With a current density of about 300 mA cm −2 the electrolysis works with a cell voltage around 1.7 V. Here, several positive effects seem to complement each other. First, the very good electrochemical activity in aqueous alkaline solution with nickel catalyst. Second, a very high number of three-phase-contact-lines in the porous structure of the gas diffusion electrode. Third, an optimized oxygen reaction with carbon in combination with Raney-Nickel. Furthermore, the positive effect of high temperatures on the efficiency (shown in the early work of F.T. Bacon) can be exploited when the temperature is increased above 80 °C. This can be realized in the AFC, since there is no sensitive membrane which must be protected against overheating as discussed in [ 34 ]. It works fine at 90 °C and more where the ohmic resistance of the potassium hydroxide is very low. This effect will be researched in more detail in the following.

Current–voltage characteristics in electrolysis mode for comparing three different cell designs: alkaline pressure electrolyzer with zero-gap design and alkaline membrane (FUMATEC, FAAM, 20 μm thickness, RANEY-Nickel and NiC GDEs); reversible AFC with 1.5 mm electrolyte gap (same electrodes); and reversible PEM fuel cell (NAFION®117 membrane, 170 μm thickness, platinum (2 mg cm −2 ) and platinum/iridium catalyst (2 mg cm −2 ) [ 32 ]

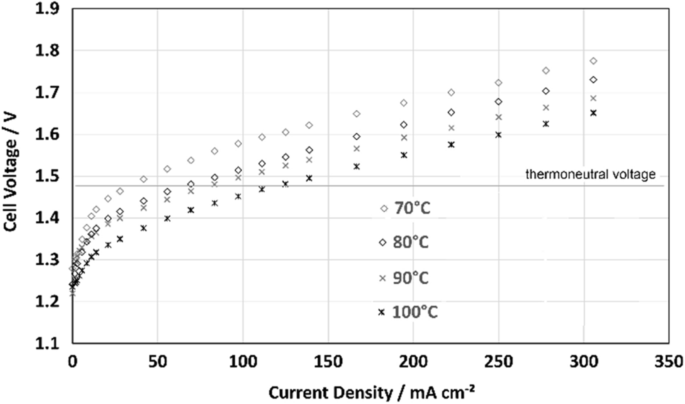

Figure 8 shows the impact of the electrolyte temperature using the electrolyte-gap design in electrolyzer mode. With rising temperature, the voltage decreases and so the efficiency is rising. The impact is significant. With an electrolyte temperature of 100 °C the cell could run at 120 mA cm −2 before reaching the thermo-neutral voltage. There are different effects which are leading to this observation. The reaction at the catalysts itself is given by the overvoltage of the cell, at higher temperatures the catalysts works more efficient and presents lower over-voltage for the same current. Also, the electrons need to pass through a layer of water molecules adhering directly at the catalyst surface, which is a temperature dependent process [ 12 ]. Concludingly, this is a remarkable result for the AFC with electrolyte gap. It shows, that for typical current densities of conventional alkaline electrolyzers it is possible to reach electrical efficiencies around 100%. This is promising for the design of highly-efficient energy storage systems with electrolyzers and fuel cells.

Current–voltage characteristics in electrolyzer mode using the AFC with 1.5 mm electrolyte-gap at different temperatures. Gas-diffusion-electrodes: hydrogen: NiH33/oxygen: NiC

On the other hand, electrolyzers with electrolyte gap are difficult to build for higher pressures as need for filling pressure containers with hydrogen. It is important to develop also membrane electrolyzers with high efficiency for this use. But, especially the mechanisms of water transport seem to be more difficult as shown below.

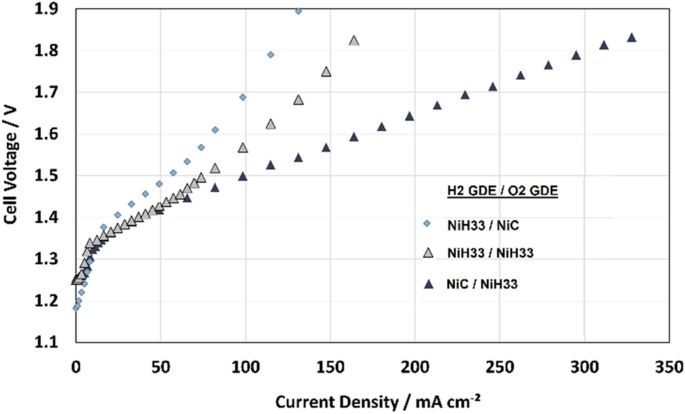

The characteristics of different electrode arrangements using a thin alkaline membrane (FAAM20) with the zero-gap design are given in Fig. 9 . At first the same electrodes were used like obtaining the best results in the AFC with electrolyte gap: a RANEY-Nickel (NiH33) at the hydrogen side and the bifunctional nickel-carbon (NiC) at the oxygen side. But, here it shows a week performance and above 100 mA cm −2 strong problems with mass transportation lead to an upward curve. With RANEY-Nickel electrodes at both sides some improvement could be made. The unexpected but best result with a straight flat curve could be obtained with interchanged electrodes: NiC at the hydrogen side and NiH33 at the oxygen side. This is surprising at first and requires a closer look into the electrochemical phenomena. RANEY-Nickel is generally a quite effective catalyst for both, the hydrogen and the oxygen evolution. The addition of carbon in the bifunctional NiC electrode was especially developed for the fuel cell mode, where it is necessary. In the electrolysis mode it obviously helps not very much for the oxygen evolution. On the other side, the carbon seems to have a positive effect at the hydrogen electrode. This can be explained by the mechanisms of mass transportation. In alkaline electrolyzers the hydroxide ions are produced at the hydrogen electrode while water is consumed. At the oxygen electrode it is the other way around. Consequently, hydroxide ions must diffuse from the hydrogen to the oxygen side while water must diffuse through the membrane and against the ion flow from the oxygen to the hydrogen side. This can lead to a dehydration of the hydrogen electrode. Here, the carbon can help since it better holds the water and has much smaller pores: < 1 μm instead of 10–40 μm at RANEY-Nickel [ 33 ]. Thus, it can be concluded that an improvement of the water management at the hydrogen electrode can be achieved with an additional carbon content. If the carbon electrode is located at oxygen side another effect occurs: the produced oxygen bubbles can settle in the fine pores of the carbon and "clog" them. This poor oxygen removal leads to a reduction of the active area and thus to poorer performance.

Current–voltage characteristics in electrolyzer mode using zero-gap design with FAAM20 and different electrode arrangements at the hydrogen and oxygen side, GDEs: NiH33 and NiC

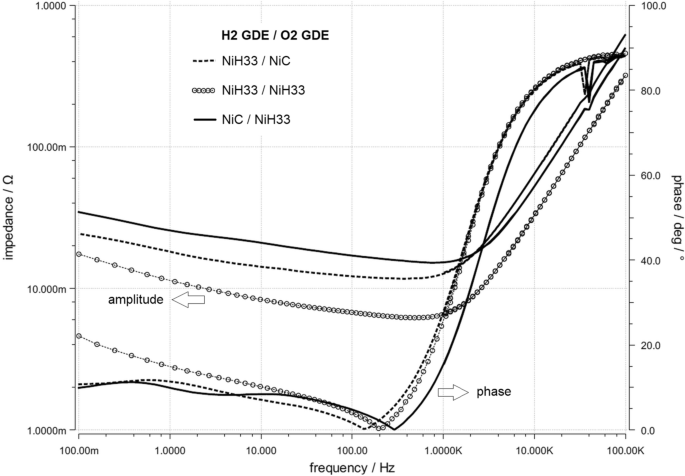

The effects described above are reflected in the impedance spectroscopy recorded during electrolysis operation (Fig. 10 ). For an improved cell design, the impedance should be low to guaranty a small internal resistance. Additionally, the phase is considered: a flat curve at low frequencies is a sign for optimized mass transport. The best mass transfer takes place in the constellation with the NiC electrode at the hydrogen side and the NiH33 at the oxygen side. Despite the lowest cell resistance with 6 mOhm, the NiH33 electrode at both sides does not offer the best performance, because as described before, the water balance is not optimal for this cell design.

Impedance spectra of the three different electrode arrangements also presented in Fig. 9 . Solid lines: H 2 :NiC/O 2 :NiH33; circle marks: H 2 /O 2 :NiH33; dashed lines: H 2 :NiH33/O 2 :NiC

It is important to note that these observations and values are only valid for the water deficit network with the Membrane FAAM-20 used here and other membranes may require a different water management. To obtain comparable results, the FAAM-Membrane was watered for at least 24 h before installation and then run in together with the electrodes at a fixed current of 1.7 V for 48 h.

4.2 Fuel Cell Mode

It was shown above that the alkaline fuel cell operation with an electrolyte gap shows a fundamentally weaker performance then the PEM fuel cell. With the bifunctional NiC catalyst only about 50 mA cm −2 could be realized, although the electrolyte temperature was set between 85 and 90 °C. The gas diffusion electrodes were supplied with pure oxygen and hydrogen at little overpressure of about 200 mbar from an external PEM electrolyzer. It could be figured out that the hydrostatic equilibrium between liquid electrolyte, capillary pressure and gas pressure is very sensitive to adjust but has a big impact on the performance. Probably, only a small part of the catalyst surface is in effective operation. Increasing gas pressure lead to some improvement with the risk that gas bubbles break through the electrode structure and block the electrolyte supply. The electrolyte feeding into the structure from the gap is also important. If no hydrophilic layer is applied the electrode will be flooded after a while with strongly decreasing performance. With a thin layer of a hydrophilic mixtures (PBI, NMP and titanium oxide) brushed at the liquid side of the electrodes some improvement could be obtained but with hardly stable operation in small pressure range. A more stable operation could be achieved with PESU separators, with tiny pores of approximately 0.1 µm size [ 33 ], pressed on both electrodes using the support structure in the electrolyte gap.

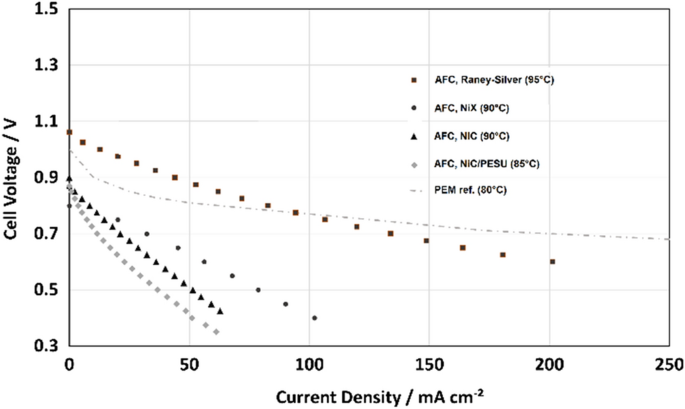

In Fig. 11 different electrodes and hydrophobic layers are investigated using the AFC in fuel cell mode. The first experiments were conducted with a NiH33 electrode at the hydrogen side and NiC electrodes at the oxygen side. Using the PSU separators results in a characteristic with the lowest performance. Additional impedance measurements showed that the internal cell resistance with 2 separators is quite high and lays in a range of about 40 mOhm. With the same electrode configuration and a brush applied separating layer of PBI, NMP and titanium oxide, the efficiency increases. This increase in performance is due to lower internal resistance of the cell and improved water transport. The three-phase boundary can be shifted by carefully varying the pressure and thus influence the performance.

Comparison of AFC with electrolyte gap with different oxygen electrodes (NiC, NiX and RANEY-Silver) all with NiH33 at hydrogen side, compared with PEM reference cell [ 29 ]

Additionally, another carbon electrode (NiX) was investigated, which is a NiC with a modified mixture. It benefits enormously from pressure and shows that the electrodes still offer further potential by optimizing the operating pressure and the chemical composition. The NiX electrode contains 5% more carbon what equals to an increase of 25% more volume and surface than the reference NiC. Finally, a high-performance silver electrode was installed which was made from a mixture of RANEY-Silver and PTFE. Very good improvement and much better performance could be obtained with the use of this electrode. At low current densities up to 100 mA cm −2 it performs with clear higher voltage than the PEM reference fuel cell. However, silver is costly and does not allow reversible operation since it will dissolve at higher voltages during electrolysis. But against the background of the development of highly-efficient energy storage with fuel cells silver must be considered as an alternative catalyst: in alkaline media with silver catalyst the highest efficiencies of all fuel cells can be achieved.

4.3 Storage Efficiencies

Concludingly, the measured cell voltages can be used to present the electrical efficiencies of the researched cell types in fuel cell and electrolyzer mode. From that the round-trip efficiency for storing electric energy can be displayed. The PEM fuel cell shows much better performance at high current densities. But, since it was the objective of the on-hand work to discuss the potential of the alkaline technology, small current densities are considered here. In the following table the efficiencies of the AFC with electrolyte gap are compared with the data of the reversible PEM fuel cell from [ 29 ] at current densities of 50 mA cm −2. (Table 2 ).

Both fuel cells are working at quite high efficiencies. But, at low current density the alkaline technology can play to its advantage. While the PEM system reaches around 55% round-trip efficiency, the AFC obtains 65%. It is remarkable since this range is comparable with conventional lead-acid batteries. Finally, the alkaline fuel cell technology has the potential for designing highly-efficient hydrogen storage systems as an alternative to batteries. On the other hand, the current densities are to low for technical use. There is still a need for research in this field.

5 Summary and Conclusion

The first investigations of the bifunctional electrodes show that these have significant potential to increase the efficiency at low cost for electrolysis process. The results with the gap design are particularly good, since a high efficiency of 300 mA cm −2 at cell voltage < 1.7 V has been achieved and the cell can also be used as a fuel cell without any modifications. Also, in the zero-gap design where the electrodes are in direct contact with the membrane, the bifunctional electrodes bring advantages as they can be used to optimize the water balance. Comparing the roundtrip efficiency with the values of a reversible PEM-Cell, especially in electrolysis mode at low densities, work can be done much more efficiently. Particularly noteworthy are the values under the thermoneutral voltage. At 95 °C in the cell, up to 100 mA cm −2 can be achieved at less than 1.47 V and thus an electrical efficiency of 100%. This does not include the required heating and pumping power. In fuel cell operation, however, the alkaline fuel cell can only compete with silver at low current densities of the PEM-Cell. Future work is in operation to achieve even more Power with the same area and less voltage. Therefore, the electrodes will be optimized resulting in more active area and less resistance. Additionally, the long-term stability of the NIC should be investigated, also because in [ 25 ] only 60 h operation were observed.

It should be emphasized that very good roundtrip efficiencies about 65% could be achieved with the AFC. These are comparable with lead-acid batteries. This is promising for the design of highly-efficient fuel cell storage systems as an alternative to batteries. However, the current densities are still too low. With the optimization of thin alkaline membrans the power density will be improved. Although silver catalyst is not suitable for a bifunctional operation, it achieves the highest fuel cell voltages of all and should be considered for future research. To save the costly silver catalyst it could be supported on carbon particles and directly coated on alkaline membranes.

IPCC, Sixth Assessment Report (2021) www.ipcc.ch/assessment-report/ar6/

EATON (2021) Fit für die Zukunft: Stromnetz braucht flexible, zellulare Struktur, Solarserver at 30th September 2021, www.solarserver.de

Kurzweil P, Dietlmeier OK (2015) Elektrochemische Speicher. Springer Vieweg, Wiesbaden

Book Google Scholar

Chen W, Liang J, Yang Z, Li G (2019) Energy Procedia 158:4363–4368

Article Google Scholar

Thomas LV, Schmidt O, Ajay G, Sheridan F, Iain S (2020) J Energy Storage 28:101230

Sternberg A, Hank C, Hebling C (2019) Treibhausgas-Emissionen für Batterie- und Brennstoffzellen-fahrzeuge mit Reichweiten über 300 km, Fraunhofer ISE

Kneer A, Jankovic J, Susac D, Putz A, Wagner N, Sabharwal M, Secanell M (2018) J Electrochem Soc 165(6):F3241–F3250

Article CAS Google Scholar

Napporn TW, Mokrini A, Rodríguez-Varela FJ (2018) Advanced electrocatalysts for low-temperature fuel cells. Springer, Cham

Google Scholar

Osman AI, Mehta N, Elgarahy AM, Hefny M, Al-Hinai A, Al-Muhtaseb AH, Rooney DW (2022) Hydrogen production, storage, utilisation and environmental impacts: a review. Environ Chem Lett 20:153–188. https://doi.org/10.1007/s10311-021-01322-8

Scheepers F, Stähler M, Stähler A, Rauls E, Müller M, Carmo M, Lehnert W (2021) Appl Energy 283:116270

Bacon FT (1969) Fuel cells past, present and future. Electrochem Acta 14:569–585

Kurzweil P (2016) Brennstoffzellentechnik. Springer Vieweg, Wiesbaden

Ledjeff K (1995) Brennstoffzellen. C.F. Müller, Heidelberg

Xue J, Zhang J, Liu X, Huang T, Jiang H, Yin Y, Qin Y, Guiver MD (2022) Toward alkaline-stable anion exchange membranes in fuel cells: cycloaliphatic quaternary ammonium-based anion conductors. Electrochem Energy Rev 5:348–400. https://doi.org/10.1007/s41918-021-00105-7

Park S, Shao Y, Liu J, Wang Y (2021) Energy Environ Sci 11:9331

Ferriday TB, Middleton PH (2021) Alkaline fuel cell technology: a review. Int J Hydrogen 46:18489–18510

Desmond JW, Gorlin Ng Y, Hatsukade T, Jaramillo TF (2013) Adv Energy Mater 3:1545

Wagner N, Schulze M, Gülzow E (2004) J Power Sources 127:264

Gamburzev S, Petrov K, Appleby AJ (2002) J Appl Electrochem 32:805

Franzen D, Ellendrof B, Paulisch MC, Hilger A, Osenberg M, Manke I, Turek T (2019) J Appl Electrochem 49:705

Gülzow E, Wagner N, Schulze M (2003) Fuel Cells 3(1–2):67–72

Yong WF, Chung T-S, Weber M, Maletzko C (2018) New polyethersulfone (PESU) hollow fiber membranes for CO 2 capture. J Membr Sci 552:305–314. https://doi.org/10.1016/j.memsci.2018.02.008

Pan ZF, Zhao TS, Tang ZK (2018) Prog Energy Combust Sci 66:141

Hodges A, Hoang AL, Tsekouras G, Wagner K, Lee C-Y, Swiegers GF, Wallace GG (2022) A high-performance capillary-fed electrolysis cell promises more cost-competitive renewable hydrogen. Nat Commun 13:1304. https://doi.org/10.1038/s41467-022-28953-x

Article CAS PubMed PubMed Central Google Scholar

Wagner E, Kohnke HJ (2020) Another chance for classic AFCs? Experimental investigation of a cost-efficient unitized regenerative alkaline fuel cell, using platinum-free gas diffusion electrodes. Fuel Cells 20(6):718–729

Dehnert K, Jäckel M, Oehr H, Rehbein U, Seitz H (1979) Allgemeine Chemie, Schroedel

Forsythe RC, Cox CP, Wilsey MK, Mueller AM (2021) Pulsed laser in liquids made nanomaterials for catalysis. Chem Rev 121:7568–7637

Article CAS PubMed Google Scholar

Wagner E, Stephan P (2009) High resolution measurement at nucleate boiling of pure FC-84 and FC-3284 and its binary mixtures. ASME J Heat Transfer 131(12):1–12

Wittstadt U, Wagner E, Jungmann T (2005) J Power Source 145:555–562

Ilseng A, Skallerud BH, Clausen AH (2016) Tension behavior of HNBR and FKM elastomers for a wide range of temperatures. Polym Test 49:128–136

Wagner E (2019) Fuel cell module. German Utility Patent DE202019001642.2

Chaudhari NK, Jin H, Kim B, Lee K (2017) Nanostructured materials on 3D nickel foam as electrocatalysts for water splitting. Nanoscale 9:12231–12247

Kohnke H-J (2006) Proceedings of ACHEMA, Frankfurt

Liu Z, Syed Sajjad SD, Gao Y, Yang H, Kaczur JJ, Masel RI (2017) The effect of membrane on an alkaline water electrolyzer. Int J Hydrogen Energy 42(50):29661–29665

Download references

Acknowledgements

The experimental investigation of the on-hand word was performed in the new fuel cell laboratory of the FRANKFURT UAS. Many thanks to the head of the FACULTY OF COMPUTER SCIENCE AND ENGINEERING for equipping the laboratory with high-quality devices. Special thank goes to the STATE OF HESSE for the funding program for universities of applied sciences with the title Research for practice . With this founding the doctoral student Erik Delp was paid for one year. Many thanks also to the master student Lennard Winter who improved the AFC design and who recorded many characteristics, partially presented in the on-hand work.

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and affiliations.

Frankfurt University of Applied Sciences, Frankfurt, Germany

Enno Wagner & Erik Delp

School of Computing and Engineering, University of Huddersfield, Huddersfield, UK

Rakesh Mishra

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Enno Wagner .

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Wagner, E., Delp, E. & Mishra, R. Energy Storage with Highly-Efficient Electrolysis and Fuel Cells: Experimental Evaluation of Bifunctional Catalyst Structures. Top Catal 66 , 546–559 (2023). https://doi.org/10.1007/s11244-022-01771-7

Download citation

Accepted : 12 December 2022

Published : 13 January 2023

Issue Date : March 2023

DOI : https://doi.org/10.1007/s11244-022-01771-7

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Bifunctional catalyst

- Gas diffusion electrodes

- Electrolyte

- Alkaline membranes

- Nickel-graphite catalyst

- Find a journal

- Publish with us

- Track your research

Hydrogen or batteries for grid storage? A net energy analysis †

Matthew A. Pellow * a , Christopher J. M. Emmott bc , Charles J. Barnhart d and Sally M. Benson aef a Global Climate and Energy Project, Stanford University, Stanford, CA 94305, USA. E-mail: [email protected] b Department of Physics, Imperial College London, London, SW7 2AZ, UK c Grantham Institute for Climate Change, Imperial College London, London, SW7 2AZ, UK d Institute for Energy Studies, Western Washington University, Bellingham, WA 98225, USA e Department of Energy Resources Engineering, Stanford University, Stanford, CA 94305, USA f Precourt Institute for Energy, Stanford University, Stanford, CA 94305, USA

First published on 8th April 2015

1 Introduction

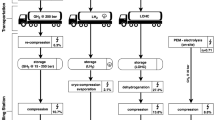

Another technology available for grid-scale energy storage is a regenerative fuel cell, in which energy is stored as hydrogen gas. 11–13 A regenerative hydrogen fuel cell system consists of a water electrolyzer, compressed hydrogen gas storage tanks, and a fuel cell ( Fig. 1 ). The system uses electricity to generate hydrogen from water in an electrolyzer. The hydrogen is stored in high-pressure tanks, and dispatched to the hydrogen fuel cell to generate electricity when desired.

Regenerative hydrogen fuel cells (RHFC's) have several characteristics that are well-suited to large-scale energy storage. They are not subject to geological requirements, which are important restrictions on pumped hydro and compressed air storage. The energy capacity and power capacity of a regenerative fuel cell can be configured independently. Storing energy in hydrogen provides a dramatically higher energy density than any other energy storage medium. 8,10 Hydrogen is also a flexible energy storage medium which can be used in stationary fuel cells (electricity only or combined heat and power), 12,14 internal combustion engines, 12,15,16 or fuel cell vehicles. 17–20 Hydrogen storage has a very low rate of self-discharge, and has therefore been proposed for seasonal storage. 8,21 The cost of energy storage in a regenerative hydrogen fuel cell is already potentially competitive with batteries in an optimized energy arbitrage system. 22 Several dozen RHFC projects have already implemented hydrogen storage, spanning a wide range of energy and power capacities ( Fig. 2 ). 12 The most common configuration among existing systems contains an alkaline water electrolyzer (AWE) and a polymer electrolyte membrane fuel cell (PEMFC). ‡

In the present study, we use net energy analysis to compare regenerative hydrogen fuel cells to other storage technologies on the basis of life-cycle energy costs. We first introduce a model to determine the ESOI e ratio of a RHFC system as a function of system parameters such as fuel cell efficiency and energy-to-power ratio. We apply this model to a RHFC system containing an alkaline water electrolyzer and a PEM fuel cell, and analyze the impact of different technology and design variables on the system's lifetime energy balance. We then use the model to analyze the energy cost or benefit that results from building new RHFC storage to complement an intermittent renewable generating facility. Finally, we compare it with a lithium ion battery storage system, which has the highest ESOI e ratio among the battery technologies currently used for grid-scale storage.

2 Methodology

2.1 esoi e ratio of a regenerative hydrogen fuel cell, 2.2 reference case values.

To determine the energy intensity of alkaline water electrolyzers (AWE's), life cycle inventory (LCI) data are required. Unfortunately, no peer-reviewed LCI's are available for alkaline water electrolyzers. However, an empirical LCI is available for an alkaline fuel cell (AFC), a 2010 study by Staffell and Ingram (Table S1, ESI † ). 39 Although AWE's and AFC's are designed differently, both employ nickel as a catalyst, at the anode of an AFC and the cathode of an AWE. 27,39–41 We judge that because of the partial overlap in this key energy-intense material, the AFC LCI provides a useful approximation when estimating the embodied energy of the AWE. From this life-cycle inventory and Ecoinvent data, 42 we determined a final value of 1.36 × 10 6 (MJ) prim /(MW) el for the cell stack of the alkaline fuel cell model analyzed by Staffell and Ingram. To convert from primary to electrical energy, we multiply by η grid = 0.30 to obtain a final value of ζ lyz,stack = 4.1 × 10 5 (MJ) el /(MW) el .

This approach necessarily introduces significant uncertainty into our estimate of ζ lyz,stack , and we examine a wide range of values in our sensitivity analysis (Section 3.2).

To determine the energy intensity of a hydrogen compressor, we consider a representative commercially available compressor (RIX Industries model 4VX-S). 43 This compressor has a capacity of 48 N m 3 h −1 (30 SCFM), which is approximately the output of a 240 kW electrolyzer, and weighs 1300 kg (3000 pounds). Since the compressor is fabricated predominantly of steel, we approximate its materials inventory as 100% steel. Using an embodied energy value for steel of 40.0 (MJ) prim kg −1 , 33 this corresponds to an embodied energy of 5.5 × 10 4 (MJ) prim . As the electrolyzer power capacity determines the hydrogen flow rate, which in turn determines the capacity required of the compressor, we normalize the energy intensity of the compressor to the power capacity of the electrolyzer. For the compressor described here, this gives an energy intensity of 2.3 × 10 5 (MJ) prim /(MW) el , or ζ comp = 6.5 × 10 4 (MJ) el /(MW) el .

To estimate the energy intensity of compressed hydrogen storage, we considered a 58 kg steel cylinder that holds 0.72 kg of hydrogen at 20 MPa. 32 To restate this mass of steel in terms of energy, we use the same value for the energy intensity of steel as the previous calculation – 40.0 (MJ) prim kg −1 – and assume that the tank is made entirely of steel. To restate this mass of hydrogen as a quantity of energy, we consider the energy content of hydrogen of 120.2 MJ kg −1 (LHV basis). The steel cylinder described here then has an energy intensity for hydrogen storage of 26.8 (MJ) prim /(MJ) LHV . We multiply by η grid = 0.30 to obtain a final value of ε st = 8.0 (MJ) el /(MJ) LHV .

2.3 ESOI e ratios of batteries and geological storage

3.1 esoi e ratio of a regenerative hydrogen fuel cell.

A RHFC energy storage facility with these technical characteristics and configuration has an ESOI e ratio of 59 (from eqn (9) ). This is higher than lithium ion batteries (ESOI e = 35), and much lower than pumped hydro (ESOI e = 830) and compressed air/natural gas (ESOI e = 1100).

3.2 ESOI e sensitivity analysis

The energy-to-power ratio R also strongly affects the system's net energy performance. This parameter is directly proportional to the discharge time of the fully-charged RHFC, a key operational consideration for energy storage facilities. The discharge time is given by R × η FC . The net energy benefit of a RHFC system is maximized with an R value under 1 × 10 4.5 s (8.8 h, providing up to 4 h of dispatchable power from the fully charged state with η FC = 0.47). However, the ESOI e ratio diminishes dramatically as R increases beyond this value ( Fig. 3 ).

The ESOI e ratio is moderately sensitive to the energy intensity of the compressed hydrogen storage, the energy intensity of the electrolyzer balance of system, and the efficiency of the electrolyzer. The energy intensity of the electrolyzer stack, whose value is the most uncertain among all the technical parameters (Section 2.2.1), is also a moderately sensitive parameter. The energy intensity of the fuel cell balance of system has almost no influence on the ESOI e ratio.

The energy-to-power ratio R has an important interaction with the technical performance parameters such as lifetime and energy intensity of the fuel cell. At small values of R , technology advances such as improvements in fuel cell lifetime and efficiency can significantly increase the ESOI e ratio of the RHFC system. However, larger values of R (providing longer dispatch duration from a single charge) diminish the impact of technology improvements on the ESOI e ratio ( Fig. 4 ).

3.3 Net energy analysis of hydrogen storage versus curtailment for renewables overgeneration

We consider a generating facility that experiences overgeneration, and we wish to determine whether installing energy storage will provide a net energy benefit over curtailment. The generating facility itself has an energy return on investment of [EROI] gen . Due to overgeneration, a fraction ϕ of the generated power must be diverted away from transmission. This diverted power may be stored for later use, or curtailed and lost ( Fig. 5 ).

Both [EROI] curt and [EROI] grid are always less than [EROI] gen . However, [EROI] grid may be greater or less than [EROI] curt , depending on the characteristics of the storage technology used. The choice of whether to build storage or accept curtailment therefore depends on the ESOI e ratio, as well as on the efficiency of the storage facility, the EROI of the generation technology, and the expected diversion ratio ϕ ( eqn (24) ).

When this quantity is positive, building new energy storage capacity will yield a greater overall return on the energy invested in building the entire grid. When this quantity is negative, curtailing the overgeneration will yield a greater overall return on the energy investment, because the energy cost of building the storage facility outweighs the benefit of storing the energy for deferred use.

Because [EROI] grid is a function of the ESOI e ratio, and the ESOI e ratio of a RHFC system is in turn a function of the energy-to-power ratio R , the relative benefit of storing overgeneration in a RHFC system depends on the energy-to-power ratio of the RHFC system ( Fig. 6 ).

For RHFC systems with low values of R , storing overgeneration from a photovoltaic system provides a net energy benefit over curtailing when the diversion ratio is above approximately 10%. At R values above 100 h (providing 47 h of continuous dispatch in our reference system), RHFC storage becomes breakeven at intermediate diversion ratios, yielding neither an energy cost nor an energy benefit compared to curtailment. However, for power from wind farms, RHFC storage is unfavorable except at high diversion ratios ( ϕ > 0.75).

Barnhart et al. recently examined the net energy impacts of building storage versus accepting curtailment for a variety of geologic and battery storage technologies coupled with wind turbines and photovoltaic panels. 24 These included pumped hydro (PHS) and compressed air (CAES) as well as lithium ion (LIB), sodium sulfur (NaS), vanadium (VRB), zinc bromine (ZnBr), and lead acid (PbA) batteries. Here, we extend this analysis with the corresponding results for a RHFC system ( Fig. 7 ). The RHFC system analyzed for this comparison is identical to the reference system ( Table 1 ) except that it contains 22 MW h (8.0 × 10 4 MJ) of hydrogen storage capacity, which provides four hours of discharge ( R = 8.5 h). The maximum dispatch time assumed in this analysis varies for each technology, and is specified in the legend of Fig. 7 . ¶¶

For wind overgeneration, building the reference case RHFC system results in a [EROI] grid equal to the corresponding result for a building a LIB storage system, and more favorable than for other battery technologies. However, the [EROI] grid for any non-geological storage option is lower than [EROI] curt for ϕ < 0.50. In contrast, for photovolatic overgeneration, RHFC storage is less favorable than LIB or NaS, but preferable to curtailing.

4 Discussion

4.1 comparison of rhfc and lib energy storage systems.

Lithium ion batteries (LIB's) have the highest ESOI e ratio (35) among a series of battery technologies being installed for grid storage ( Fig. 8 ). 46 Energy storage in hydrogen, using the reference case RHFC system, has a ESOI e ratio of 59. This indicates that one joule of energy invested in manufacturing a RHFC system enables more output from energy storage than a joule invested in manufacturing a LIB system.

The value of η * for a storage system is strongly influenced by the system's round-trip efficiency, rather than by its materials requirements. Because E life out < E life in , η * always lies between zero and unity. For the RHFC system, the embodied energy is negligible compared to the energy inputs during operation, so η * for the RHFC system is approximately equal to its round-trip efficiency of 0.30. For the LIB, the embodied energy is small compared to the energy inputs during operation, but is not negligible, so the LIB's η * of 0.83 is close to, but slightly lower than, its round-trip efficiency of 0.9.

These two different energy return ratios quantify two different dimensions of energy performance. The higher ESOI e ratio of the reference case RHFC system reflects its more efficient use of manufacturing energy to dispatch the same unit of electrical energy from storage. The LIB's higher overall energy efficiency ( η *) reflects its greater efficiency in handling the energy stored in the system during its operational life.

Although a longer PEMFC stack lifetime increases the ESOI e ratio, it has no effect on the overall energy efficiency of the system. This is because over the lifetime of the system, almost all the energy costs are due to efficiency losses, not to manufacturing the system ( Table 5 ).

Lithium ion batteries contain several materials that are directly involved in storing electric charge: a lithium intercalation compound at the cathode, highly reduced carbon at the anode, a lithium electrolyte, and a separator membrane. ††† These four active charge-storing materials in a lithium ion battery account for approximately 40% of the energy required to manufacture the battery (Table S6, ESI † ). 49,50

In a RHFC system using conventional cylinders to store compressed hydrogen gas, the only material directly involved in storing energy is the steel used to fabricate the cylinders. In our reference case RHFC system, the energy-storing material – the steel pressure vessel – accounts for only 26% of the embodied energy (Table S3, ESI † ). In an otherwise identical RHFC system that uses composite cylinders for hydrogen storage (instead of more energy intensive steel cylinders), the storage component represents only 12% of the system's embodied energy. The materials that perform the intrinsic energy storage function in a LIB system are more energetically expensive than in an RHFC system, as a share of the total manufacturing energy costs.