Welcome to ArcelorMittal Automotive space

This is your personal space on ArcelorMittal's global automotive website. You can keep your favorite ArcelorMittal automotive web pages and configurations in a safe place for later access on any device, anytime in the future.

In this space, you can find:

- Pages on this site you have saved as favorites

- The configurations that you have created in the 3D car configurator using ArcelorMittal’s best-in-class solutions

- Your e-alert preferences for ArcelorMittal’s latest automotive news

I'm not registered. Register now.

Registration

Sign up for Automotive and enjoy the benefits by receiving our newsletters, downloading software, saving your bookmarks, sending it to your colleagues and much more. If you have any questions you can contact us at [email protected] .

All fields with (*) are required

I'm already registered. Login now.

Tailor your ArcelorMittal Automotive web experience

If you want, you can tailor your web experience on this automotive website to your personal needs. By selecting your job profile and/or region (both optional) you enable us to personalize the content you see on this website. No matter which job profile or region you select, you will always have unlimited access to all the information on this website. The only thing that changes is that you will be offered more tailored content. As well as your profile and region, we also use your browsing history on this website to remember your personal preferences and identify the most appropriate content for you. We are confident that this will help you to find the inspiration you are looking for on the ArcelorMittal automotive website.

My ArcelorMittal Automotive space

This is your personal space on ArcelorMittal’s global automotive website. You can keep your favorite ArcelorMittal automotive web pages and documents in a safe place. In this space, you can find:

- Your personal version of ArcelorMittal’s global automotive product catalogue

- A list of the personal car configurations that you have created in our 3D car configurator using ArcelorMittal’s best-in-class solutions

By logging into this website, you help us to offer you the most personalized experience possible. No matter what device or browser you use, your personal preferences, saved documents and favorited pages will always be accessible. No pages require a login to view content. So there is absolutely no obligation to create a login for this website. All information on this website is available to every visitor, without limits.

Please also check our privacy message which explains how we comply with the EU’s general data protection regulation (GDPR) and other relevant privacy laws.

Customize your experience by creating an account

You can store your preferences, favorite ArcelorMittal automotive web pages and documents in a safe place, accessible at any time, from any device.

- Your personal version of ArcelorMittal’s global automotive steel product catalogue

- Access to the car configurations that you have created in the 3D car configurator using ArcelorMittal’s best-in-class solutions

By creating an account for this website, you help us to offer you the most personalized experience possible.

Register now Remind me later

Don't ask me again

Privacy policy

Log in to your ArcelorMittal automotive account

To avoid spam, we must be able to identify the sender of the e-mail. Therefore, we kindly ask you to sign in or make an account first.

Login to my account Create account

- Flat products - our global offer

- 1st Gen AHSS

- TRIP steels

TRIP (TRansformation Induced Plasticity) steels

Description.

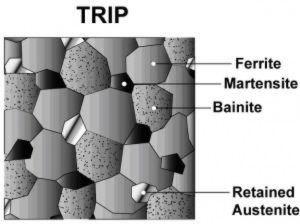

TRIP steels offer an outstanding combination of strength and ductility as a result of their microstructure. They are thus suitable for structural and reinforcement parts in complex shapes. The microstructure of these steels consists of islands of hard residual austenite and carbide-free bainite dispersed in a ductile ferritic matrix. Austenite is transformed into martensite during plastic deformation (TRIP: TRansformation Induced Plasticity effect), enabling greater elongation to be achieved which endows these steels with their excellent combination of strength and ductility.

These steels have considerable strain hardening capacity which endows them with good aptitude for strain redistribution and hence excellent drawability.

In the course of the manufacturing stages of parts, the tensile strength of TRIP steel increases sharply compared to its reference value for flat metal, both under the effect of local stamping strains and BH (Bake Hardening) effect during the paint process. These effects can be used to optimise the design of the part, especially in terms of crash behaviour. See below.

Applications

As a result of their high energy absorption capacity and fatigue strength, TRIP steels are particularly well-suited for automotive structural and safety parts such as crossmembers, longitudinal beams, B-pillar reinforcements, sills and bumper reinforcements.

ArcelorMittal has extensive data on the forming and service properties of the TRIP family of steels. A team of experts is available to carry out specific studies based on modelling or laboratory tests to incorporate these steels at the design stage.

B-pillar reinforcement in CR450Y780T-TR-EG (thickness: 1.2 mm)

Bumper cross member in CR450Y780T-TR-EG (thickness: 1.6 mm)

Designation and standard

Cold rolled steel.

Uncoated (EN 10338: 2015): Steel grade name Electrogalvanized (EN 10338: 2015 + EN 10152: 2017): Steel grade name+ZE Galvannealed (EN 10346: 2015): Steel grade name+ZF Extragal ® (EN 10346: 2015): Steel grade name+Z

VDA 239-100

Uncoated: Steel grade name-UNC Electrogalvanised: Steel grade name-EG Galvannealed: Steel grade name-GA Extragal ® : Steel grade name-GI

Mechanical properties

A 80mm %: Percentage elongation after fracture using a specimen with gauge length L 0 = 80 mm (ISO 6892-1 type 2 (EN20x80)) A 50mm %: Percentage elongation after fracture using a specimen with gauge length L 0 = 50 mm (ISO 6892-1 type 1 (ASTM12.5x50) or type 3 (JIS25x50) A%: Percentage elongation after fracture using a proportional specimen with L 0 = 5.65 (So) 1/2 Ag %: Percentage plastic extension at maximum force BH 2 : Increase in yield strength between a reference condition after a 2% plastic pre-strain and the condition obtained after heat treatment (170°C-20minutes)

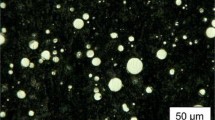

Typical CR450Y780T-TR-EG microstructure (residual austenite fraction approx. 18%)

Typical CR400Y690T-TR-GI microstructure (residual austenite fraction approx. 10%)

Chemical composition

Global availability.

- Global view

- Europe region

- North America region

- South America region

- South Africa region

Under development Customer trials Commercial unexposed only Commercial exposed and unexposed

Under development Customer trials Commercial unexposed only Commercial exposed and unexposed

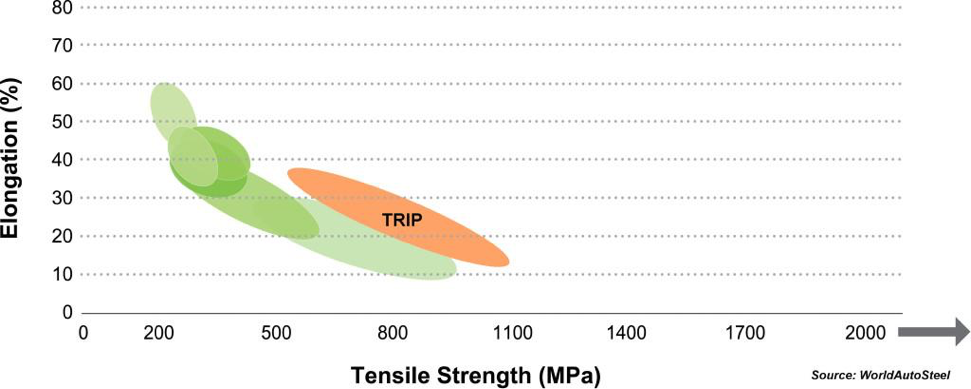

TRIP steels offer high ductility relative to their tensile strength. For example, CR450Y780T-TR boasts uniform elongation comparable to that of a type CR3 deep drawing grade.

The illustration below shows examples of forming limit curves for 1.5 mm thick CR400Y690T-TR and CR450Y780T-TR steels. Their formability is superior to that of a lower strength CR330Y590T-DP steel.

Forming limit curves for CR400Y690T-TR-GI and CR450Y780T-TR-EG (thickness: 1.5 mm) (ArcelorMittal model for Europe)

Forming limit curves for CR400Y690T-TR-GI and CR450Y780T-TR-EG (thickness: 1.5 mm) (Keeler model for North America)

Please contact us for more information on forming TRIP steels.

Resistance spot-welding

TRIP steels can be readily welded using conventional welding processes, provided the welding parameters are adjusted.

The table below gives examples (for information only) of spot welding parameters for CR400Y690T-TR-GI and CR450Y780T-TR-EG matching joints, in accordance with the ISO 18278-2 standard:

MAG arc welding

MAG (Metal Active Gas) arc welding employs a filler wire in a protective gas shield. It can be used for thicknesses greater than 0.8 mm. MAG weldability of CR450Y780T-TR has been assessed using CMOS (Welding Operating Procedure Characterisation based on standards EN 288 and EN 25817) for 1.5 mm thick butt joints. Heat input is of the order of 2 kJ/cm.

As a result of its chemical composition, CR450Y780T-TR typically has a relatively high carbon equivalent of the order of 0.50. However, no particular precautions are needed to prevent cold cracking. In actual fact, the reduced thicknesses employed (< 2 mm) minimise restraint stresses during welding.

The most appropriate combination for MAG welding of CR450Y780T-TR in a thickness range of approx. 1.5 mm is as follows:

- Filler: G3Si1 type in accordance with EN 440

- Shielding gas: Ar + 8% CO2

- (M21 in accordance with EN 439)

The CMOS evaluation shows satisfactory overall weld behaviour meeting the mechanical strength criteria set out in the standards, given that:

- Bends are acceptable up to 120° and crack on the reverse side at 180°;

- All tensile test failures occur in the base metal thanks to base metal/filler metal dilution, even with G3Si1 wire.

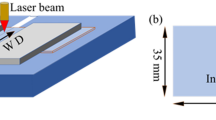

Laser welding

Laser welding tests have revealed no particular difficulties. Laser lap welding is particularly suitable for TRIP/TRIP joints.

Based on extensive shop-floor experience in characterising its products, ArcelorMittal is able to provide technical assistance in adjusting the welding parameters for all steels in the TRIP range.

Fatigue strength

Due to their high mechanical strength, TRIP grades boast significantly better fatigue properties than conventional steels.

Examples of Wöhler curves for a variety TRIP grades are shown in the two graphs below. The curves plot maximum stress versus number of cycles to failure. They are calculated for two loading ratios: tension-compression R=-1 and tension-tension R=0.1.

The graph below shows the low-cycle fatigue or E-N curves for the same steels. The curves plot strain amplitude versus number of reversals to failure (one cycle equals two reversals). Other high and low cycle fatigue data can be provided on request.

ArcelorMittal can make a TRIP steel fatigue database available to its customers.

Impact strength

As a result of their very high tensile strength, TRIP steels are particularly suitable for parts designed to absorb energy in an impact.

TRIP steels have been characterised in dynamic axial compression tests using an omega structure with a spot-welded closure plate at an impact velocity of 56 km/h. These tests have demonstrated the very positive impact behaviour of these steels.

Weight-reduction potential compared to that of a CR340LA steel (reference)

These results are obtained for test pieces produced by bending. Strain-hardening during drawing enhances the energy absorption capacity of this grade. In order to fully exploit the potential of TRIP steels, the metal properties after forming (hardening) rather than those of the initial blank should be used in the design stage. Crush tests have shown a 9% gain in energy absorption of drawn parts compared to parts obtained by bending.

You may also be interested in

Explore our steel solutions for bev and ice vehicles, search our products.

By products

By strength, by product reference, by coatings, by applications, create your personal catalogue, get in touch with our experts.

S-in-motion ® solutions

Innovation & sustainability, tailored blanks.

- Drawing steels

- HSLA steels

- Bake hardening steels

- Solid solution steels

- Dual Phase steels

- Complex Phase steels

- Ferrite-bainite steels

- Fortiform ®

- MartINsite ®

- Usibor ® and Ductibor ®

- Alusi ® -AS

- Extragal ® -GI

- Ultragal ® -GI

- Galvannealed-GA

- Zagnelis ® Protect-ZMP

- Zagnelis ® Surface-ZMS

- Electrogalvanized-EG

- Surface treatments

- Jetgal ® -ZV

- iCARe ® electrical steels

- iCARe ® Save

- iCARe ® 420 Save

- iCARe ® Torque

- iCARe ® Speed

- Coatings for iCARe ®

- High carbon steels

- Extragal ® double-side pure zinc galvanized steel

- Galvannealed zinc-iron alloy coated steels

- Zagnelis ® Protect Double-sided ZnMgAl galvanized steel

- Zagnelis ® Surface Double-sided ZnMgAl galvanized steel

- Galfan ® Steel coated with galfan zinc-aluminium alloy

- Steel coated with Alusi ®

- Electrogalvanized sheet coated on one or both sides

- Surface treatment

- Jetgal ® Cold stamping steel coated with zinc from an innovative & environmentally friendly process

Innovation & Sustainability

S-in motion ® solutions

- Advantages of laser welded blanks

- Applications for laser welded blanks

- Laser welded blanks for hot stamping

- Laser welded blanks for cold stamping

- Unwelded blanks – die cut blanks

- Unwelded blanks – laser cut blanks

- Patched blanks

- Multi Part Integration

- One-part rear H-frame

- Double door ring

- Ductibor ® / Usibor ®

- Laser ablation

- Nesting optimization

- Co-engineering

- Feasibility analysis

- Quality assurance

- Prototyping

Sustainability

News, events and stories

- an automotive engineer

- an automotive material purchaser

- an automotive top manager

- an automotive journalist

- an investor

- an influencer

- an ArcelorMittal colleague

- a student/professor

- an environmentalist

I am especially interested in information about automotive steel for…

This is your personal space on ArcelorMittal's global automotive website. You can keep your favorite ArcelorMittal automotive web pages and documents in a safe place

Configure this website

What are TRIP Steels?

WHAT ARE TRIP STEELS (Transformation Induced Plasticity Steels)?

TRIP Steels (Transformation Induced Plasticity Steel) are part of the Advanced High-Strength Steel (AHSS) family.

The microstructure of TRIP steels consists of at least five-volume percent of retained austenite, which is embedded in a primary ferrite matrix. The microstructure also contains hard phases like bainite and martensite in varying amounts.

TRIP steels are notable due to the higher carbon content than other members of the AHSS family, such as dual phase steels. They typically require the use of an isothermal hold at an intermediate temperature, which produces some bainite. Silicon and aluminum are added in order to both accelerate the ferrite and bainite formation process, as well as avoiding carbide buildup in the bainite region of the material.

Greater silicon, aluminum, and carbon content of TRIP steels result in large fractions of retained austenite in the material’s final microstructure. The increased carbon content also stabilizes the retained austenite phase below the usual ambient temperature.

Changing the carbon content helps to control the strain level at which the austenite begins to transform into martensite. At low carbon levels, the transformation of the retained austenite will begin almost immediately upon deformation, which will then improve the formability and work hardening rate during the stamping process.

At higher carbon content, the transformation will occur only at strain levels beyond those utilized during the forming processing. The retained austenite remains after the final stage of the forming process at these higher carbon levels – the transformation into martensite will occur only during subsequent deformation; in the case of automobiles, an example would be a crash event.

PROPERTIES OF TRIP STEELS

TRIP Steels can be produced as hot-rolled, cold-rolled, or hot dip galvanized, with a strength range from 500 MPa to 800 MPa.

TRIP Steels are highly sought after due to their high work hardening rate, which is created by the hard second phases that are dispersed in the soft ferrite during deformation. Despite the fact that initial work hardening rate of the material is lesser than that of, say, dual phase steels, TRIP steels sustain their hardening rate at much higher strain levels, where DP steel’s work hardening rate would deteriorate.

As a result of the high work hardening rates, TRIP steels also have substantial stretch forming properties.

The high strain hardening capacity and mechanical strength make these steels an excellent candidate for automotive parts that require a high energy absorption capacity. TRIP steels also have a strong bake hardening following deformation, which even further improves their crash performance.

To summarize TRIP steel’s properties:

- Work hardening – When compared to other advanced high-strength steels, TRIP steels exhibit and retain a higher work hardening rate at higher levels of strain.

- Formability – As a byproduct of the high work hardening rate, these steels have substantial stretch forming properties, and can be put through stamping processes in a relatively stable manner.

- Bake hardening – TRIP steels have a very high bake hardening capacity, and can by doing so can increase their yield strength by close to 70 MPa.

- Product mass reduction capacity – Due to the above characteristics, these steels are good candidates for weight reduction and part down gauging techniques.

APPLICATION OF TRIP STEELS IN AUTOMOBILES

TRIP steels are excellent for automotive parts that require high work hardening during crash deformation and large amounts of energy absorption.

They are also very well-suited for creatingcomplicated, hard-to-form parts, which is a result of their high formability and work hardening attributes. Thus, they are handy for complex reinforcement and structural parts.

Current production grades of TRIP steels and example automotive applications:

TRIP 350/600 Frame rails, rail reinforcements

TRIP 400/700 Side rail, crash box

TRIP 450/800 Dash panel, roof rails

TRIP 600/980 B-pillar upper, roof rail, engine cradle, front and rear rails, seat frame

TRIP 750/980

About National Material L.P. – National Material Limited Partnership and its affiliates have a long history of quality and service dating back to 1964. Since its founding, National Material L.P. has grown to over 30 business units and is now one of the largest suppliers of steel in America. The National Material group of industrial businesses consists of the Steel Group, Stainless and Alloys Group, Raw Material Trading Group, Aluminum Group, and Related Operations.

Visit National Material: https://www.nationalmaterial.com or call (U.S.) 847-806-7200.

Share This Story, Choose Your Platform!

Related posts.

Processing Steel in the U.S. – Metal Forming 101

New Year, Great Outlook for Metals Processor National Material Company

Steel Tubing for Solar Trackers & Solar Applications

Aluminum for Electric Vehicles: Aluminum is The Future of Automotive

Steel Processor Partnership Spotlight: Aluminum Slitting Services

Characterization of the Fracture Toughness of TRIP 800 Sheet Steels Using Microstructure-Based Finite Element Analysis 2009-01-0800

Recently, several studies conducted by automotive industry revealed the tremendous advantages of Advanced High Strength Steels (AHSS). TRansformation Induced Plasticity (TRIP) steel is one of the typical representative of AHSS. This kind of materials exhibits high strength as well as high formability. Analyzing the crack behaviour in TRIP steels is a challenging task due to the microstructure level inhomogeneities between the different phases (ferrite, bainite, austenite, martensite) that constitute these materials. This paper aims at investigating the fracture resistance of TRIP steels. For this purpose, a micromechanical finite element model is developed based on the actual microstructure of a TRIP 800 steel. Uniaxial tensile tests on TRIP 800 sheet notched specimens were also conducted and tensile properties and R-curves (Resistance curves) were determined. The comparison between simulation and experimental results leads us to the conclusion that the method using microstructure-based representative volume element (RVE) captures well enough the complex behavior of TRIP steels. The effect of phase transformation, which occurs during the deformation process, on the toughness is observed and discussed.

SAE MOBILUS

Subscribers can view annotate, and download all of SAE's content. Learn More »

Access SAE MOBILUS »

DP590 GI Mechanical Property Variability and Structural Response CAE Studies

2009-01-0799

View Details

Forming High-Strength Steels

2009-01-0802

Advanced Material Characterizations and Constitutive Modeling for AHSS Springback Predictions

2010-01-0980

Microstructural Effects on the Mechanical Integrity of a TRIP-800 Steel Welded by Laser-CO 2 Process

- Published: 06 July 2012

- Volume 22 , pages 607–612, ( 2013 )

Cite this article

- G. Y. Perez-Medina 1 , 2 , 3 ,

- H. F. López 2 ,

- P. Zambrano 3 &

- F. A. Reyes-Valdés 1

291 Accesses

7 Citations

Explore all metrics

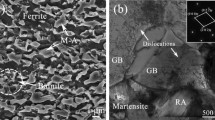

In this study, a TRIP-800 steel was welded using a Laser CO 2 process, and the resultant microstructures were characterized by optical, scanning, and transmission electron microscopy (TEM) means. It was found that the microstructure of the steel in the as-received condition consisted of ferrite, bainite, and retained austenite (RA), including some martensite. In particular, TEM observations indicated that the developed martensites were high carbon twinned martensites. It was found that laser beam welding (LBW) promoted the development of up to 23% martensite in the fusion zone (FZ) and up to 30% in the heat-affected zone (HAZ). In addition, determinations of RA using x-ray diffraction indicated that the amount of RA developed in the FZ was relatively small (<6%). Confirmation for the relatively large amounts of martensite in both the FZ and HAZ was indirectly made by the shape of microhardness profiles, which resembled a “top hat.” Tensile testing in welded strips indicated a loss of strength and ductility. An examination of the fracture surfaces indicated that the steel fractured in a brittle fashion at the HAZ-BM interface. Apparently, the development of relatively large amounts of martensite in the HAZ reduced the steel toughness. In turn, this indicated that LBW leads to martensite embrittlement in the HAZ regions, but not at the parting line of the FZ.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Selective laser melting of ultra-high-strength TRIP steel: processing, microstructure, and properties

J. Sander, J. Hufenbach, … U. Kühn

Effect of welding speed on microstructure and mechanical properties of laser-welded transformation induced plasticity (TRIP) steels

Tao Wang, Mei Zhang, … Wen-heng Wu

Influence of Laser Power on Microstructure and Mechanical Properties of Laser Welded Medium Manganese Transformation-Induced Plasticity Steel

Wangwang Yu, Haijun Pan, … Lin Liu

N. Kapustka and C. Conrardy, Effect of GMAW Process and Material Conditions on DP 780 and TRIP 780 Welds, Weld. J. , 2008, 87 , p 135–149

Google Scholar

K. Badri and P. Narayanan, Welding TRIP Steels, U.S. Cl. 428/683, US20100227196 A1, 4 Mar 2009, 9 Sept 2010

I.D. Choi et al., Deformation Behaviour of Low Carbon TRIP Sheet Steels at High Strain Rates, ISIJ Int. , 2002, 42 (12), p 1483–1489

Article CAS Google Scholar

J.E. Gould, L.R. Lehman, and S. Holmes, A Design of Experiments Evaluation of Factors Affecting the RSW of High-Strength Steels, Proc. Sheet Metal Welding Conference VII , AWS, Detroit, 1996

J.E. Gould and D. Workman, Fracture Morphologies of RSW Exhibiting Hold Time Sensitivity Behavior, Proc. Sheet Metal Welding Conference VIII , AWS, Detroit, 1998

A.K. De, J.G. Speer, and D.K. Matlock, Color Tint-Etching for Multiphase Steels, Adv. Mater. Process. , 2003, 161 , p 27–30

CAS Google Scholar

J. Chen, K. Sand, M.S. Xia, C. Ophus, R. Mohammadi, M.L. Kuntz, Y. Zhou, and D. Mitlin, TEM and Nanoindentation Study of Weld Zone Microstructure of Diode Laser Joined , Metals and Materials Society and ASM International 2008, Materials Park, 2008

M. De Meyer and D.B.C.D. Cooman, 41st MWSP Conference Proceedings , ISS, Baltimore, 1999, 483 p

G.R. Speich, Tempering of Low Carbon Martensite, Trans. ASM , 1969, 26 (1), p 1–10

J.E. Gould, S.P. Khurana, and T. Li, Predictions of Microstructures When Welding Automotive Advanced High-Strength Steels, Weld. J. , 2006, 85 , p 111s–116s

M.V. Li and D.V. Niebuhr, A Computational Model for the Prediction of Steel Hardenability, Metall. Mater. Trans. , 1998, 29B (6), p 661

H.K.D.H. Bhadeshia and L.-E. Svensson, Mathematical Modeling of Weld Phenomena , H. Cerjack and K.E. Easterling, Ed., Institute of Metals, London, 1993, p 109-180

H.K.D.H. Bhadeshia, A Thermodynamic Analysis Of Isothermal Transformation Diagrams, Metal Sci. , 1982, 16 , p 159–165

Download references

Author information

Authors and affiliations.

Corporación Mexicana de Investigación en Materiales, Saltillo, Coahuila, Mexico

G. Y. Perez-Medina & F. A. Reyes-Valdés

Materials Department, University of Wisconsin-Milwaukee, 3200 N. Cramer Street, Milwaukee, WI, 53201, USA

G. Y. Perez-Medina & H. F. López

Universidad Autónoma de Nuevo León, FIME, Av. Pedro de Alba S/N. Col Ciudad Universitaria, San Nicolás de los Garza, Nuevo León, Mexico

G. Y. Perez-Medina & P. Zambrano

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to H. F. López .

Rights and permissions

Reprints and permissions

About this article

Perez-Medina, G.Y., López, H.F., Zambrano, P. et al. Microstructural Effects on the Mechanical Integrity of a TRIP-800 Steel Welded by Laser-CO 2 Process. J. of Materi Eng and Perform 22 , 607–612 (2013). https://doi.org/10.1007/s11665-012-0282-4

Download citation

Received : 19 February 2012

Published : 06 July 2012

Issue Date : February 2013

DOI : https://doi.org/10.1007/s11665-012-0282-4

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Find a journal

- Publish with us

- Track your research

Springback evaluation for TRIP 800 steel sheets by simple bending tests

- Article contents

- Figures & tables

- Supplementary Data

- Peer Review

- Reprints and Permissions

- Cite Icon Cite

- Search Site

F. J. Avellaneda , V. Miguel , J. Coello , A. Martínez , A. Calatayud; Springback evaluation for TRIP 800 steel sheets by simple bending tests. AIP Conf. Proc. 30 April 2012; 1431 (1): 140–147. https://doi.org/10.1063/1.4707560

Download citation file:

- Ris (Zotero)

- Reference Manager

TRIP steels, or Transformed Induced Plasticity steels, have excellent mechanical properties if compared with conventional steels. Strain hardening is also greater, thus they offer a good combination of strength and formability properties that may be justified by the multiphase structure of these steels. The highlighted characteristic of these steels is that they modify the microstructure with the deformation process as part of the austenite transforms to martensite, with the consequent change of the material properties. One of the main problems of TRIP steels is strong elastic recovery, or springback, after forming. In this work, the springback phenomenon is evaluated by bending tests and the influence of the variables involved in it is determined. The factor found to affect material recovery the most was the bending angle. Experimental bending forces do not agree with theoretical predictions.

Sign in via your Institution

Citing articles via, publish with us - request a quote.

Sign up for alerts

- Online ISSN 1551-7616

- Print ISSN 0094-243X

- For Researchers

- For Librarians

- For Advertisers

- Our Publishing Partners

- Physics Today

- Conference Proceedings

- Special Topics

pubs.aip.org

- Privacy Policy

- Terms of Use

Connect with AIP Publishing

This feature is available to subscribers only.

Sign In or Create an Account

- Tour Account ›

- Travel Forum ›

- Travel Forum

A trip to Moscow

I'm going to organize a trip this summer. I want to plan everything. I’ll fly from London to Moscow, and I also want to visit St. Petersburg. Could you, please, advise me what places I should visit? I’ll stay in Moscow for about 10 days before going to St. Petersburg. Thank you!

Not a country I’d be spending my money in at the moment.

Ditto. Ditto!

I don't really see the point of shunning a country because you don't agree with its leader and/or its government. Would you go to Italy? China? Tourist dollars are more likely to get into the hands of the people rather than any corrupt bureaucracy and meeting friendly tourists might just change the locals opinions of foreigners and even give them some information they don't get from local news media.

Hopefully , I won't be starting a war here , but I must say I agree with Chani's comments . Having taken three year visas in 2015 , we have been to Moscow and St; Petersburg ( once to Moscow , and twice to St Petersburg ) . The History , Art , Music ( I am a classically trained musician ) and Culture , fascinate us . Much to experience there and advance preparation is essential , To get a good grounding for your visit , read this lavish and detailed book by Suzanne Massie , it's one of the best ways to immerse yourself in what you will experience - https://www.amazon.com/Land-Firebird-Beauty-Old-Russia/dp/096441841X/ref=sr_1_1?ie=UTF8&qid=1521652009&sr=8-1&keywords=land+of+the+firebird+massie&dpID=51CPK13XKGL&preST=_SX218_BO1,204,203,200_QL40_&dpSrc=srch

And while leaders of such countries can point to foreign visitor numbers as a sign of support ? I also believe that personal safety for certain travellers, especially obvious minorities, cannot be guaranteed, as fervent nationalism increases, and tolerance levels evaporate. Just as I may decide against a purchase at the supermarket because of a company’s behaviour, ethics will always be a consideration.

Well, I'd argue supermarket ethics does not readily translate to travel ethics - the latter is far more complex. Personally, I see the whole "vote with my hard-earned travel dollar" approach as overly simplistic, but if it's your position - I totally respect it.

What I don't understand is members volunteering ethical guidance in response to what seems an innocuous request for travel-related information.

Note a discussion on ethics hosted a year ago by the Webmaster of this very forum.

https://community.ricksteves.com/travel-forum/general-europe/travel-ethics-612334a0-0ca1-4128-b088-c13d1d8a91c3

I appreciate Rick Steves' point of view in his "Travel As A Political Act". That said, Putin's Russia is not a place I would support. But, to each his or her own....

From a practical point of view, travel between the two countries can be difficult. I understand the Russians who traveled in the US this past winter had to go to the US Embassy in the country of Georgia to get visas because the Russians expelled American embassy personnel. If you do travel to Russia, you may be on your own. See the American travel advisory: https://travel.state.gov/content/travel/en/traveladvisories/traveladvisories/russia-travel-advisory.html

Travel Advisory January 10, 2018 Russia – Level 3: Reconsider travel Reconsider travel to Russia due to terrorism and harassment. Some areas have increased risk. Read the entire Travel Advisory U.S. citizens are often victims of harassment, mistreatment, and extortion by law-enforcement and other officials. U.S. consular assistance to detained individuals is often unreasonably delayed by Russian officials. Russia also enforces special restrictions on dual U.S.-Russian nationals. Due to the Russian government-imposed reduction on U.S. diplomatic personnel in Russia, the U.S. government has reduced ability to provide services to U.S. citizens.

We have traveled to Moscow and St. Petersburg over the past few years. As in the US, most of the people we encountered helpful and not particularly political. In Moscow, we stayed at The Garden Ring Hotel which was a close walk to the metro. The hotel was very comfortable and quiet for being in the city. We loved the art museums and the Georgian restaurants. In St. Petersburg, we stayed at both The 3Mosta hotel near the Hermitage and the Art Hotel Demetra.. In St. Petersburg, we especially liked the Hermitage and Russian museum. Learning the Cyrillic alphabet and having a good map is a must.

As I think the point about ethical considerations has been made, please keep future replies more specific to the question at hand. Thanks.

Either read a good travel book or book a guide who can personally take you to the best places that interest you and tell about the sights you're seeing. We used Dan Petrov on 2 different trips to Moscow and found him to be wonderfully friendly and witty not to mention super knowledgeable.

Latest advice, Australian Governmemt, 1 April 2018. “Due to heightened political tensions, you should be aware of the possibility of anti-Western sentiment or harassment. While the Australian Government is not aware of any increased difficulties for Australians travelling in Russia at this time, you should follow the security and political situation closely and keep up to date with this travel advice. Remain vigilant, avoid any protests or demonstrations and avoid commenting publicly on political developments.”

We very much enjoyed our group trip to Moscow and St Petersburg last year. excellent guides and accommodations. While Steven who has replied here has excellent advice, ( and we took advantage of it), we felt an organized tour really facilitated our enjoyment of the country. You may want to consider a combination of an organized tour and than adding independent days . Some of the Australians on the tour had arrived a couple of days earlier than the tour stated and then some stayed later. If we were to go again (which I would), that"s how I would do it. And I must say , it was enlightening to have conversations with the Russian tour guides and the non Americans about the current world situation. Not that we went into any great depth, but I think we all went away with a little more understanding. Top places: allow lots of time in St Petersburg at the Hermitage- take a separate day for the Impressionist building. In Moscow, the Russian Art Museum was amazing.

Solid advice from Australian government quoted above, especially the keeping up to date part.

I checked the current version (Sep 18) of that advisory - and it hasn't been updated much. In fact, some sections don't seem to have changed since 2005 - their recommendations for importing/exporting currency and financial instruments, for example, are at least five years behind.

I do like reading governmental travel advisories for entertainment purposes - for instance, up until very recently the US one sternly advised potential travelers that Moscow was largely a cash-based economy (couldn't be further from the truth) and warned about intrinsic dangers of gypsy cabs (which had all but disappeared by 2015).

This topic has been automatically closed due to a period of inactivity.

IMAGES

COMMENTS

TRIP steels offer an outstanding combination of strength and ductility as a result of their microstructure. They are thus suitable for structural and reinforcement parts in complex shapes. The microstructure of these steels consists of islands of hard residual austenite and carbide-free bainite dispersed in a ductile ferritic matrix. Austenite is transformed into martensite during plastic ...

TRIP Steels can be produced as hot-rolled, cold-rolled, or hot dip galvanized, with a strength range from 500 MPa to 800 MPa. TRIP Steels are highly sought after due to their high work hardening rate, which is created by the hard second phases that are dispersed in the soft ferrite during deformation. ... To summarize TRIP steel's properties:

TRIP steel are a class of high-strength steel alloys typically used in naval and marine applications and in the automotive industry. [1] TRIP stands for "Transformation induced plasticity," which implies a phase transformation in the material, typically when a stress is applied. These alloys are known to possess an outstanding combination of ...

The classical steel with tensile strengths of up to 800 MPa and exceptional deep-drawing properties. TRIP (transformation-induced plasticity) steels are part of the ahss classic product line of voestalpine in the field of ultralights. They maintain high ten-sile strength while achieving excellent deep-draw-ing properties through extraordinary ...

OPEN ACCESS ARTICLE TRIP 800 steel and DP 1000 steel welded by using the electron beam welding (EBW) method were investigated in this study. Martensite was a dominant phase at the fusion zone (FZ ...

The chemical composition of the TRIP steel is given in Table I. Table II shows the mechanical properties of the TRIP steel in the form of 1.6 mm thick sheet. Tensile bars have been cut from the steel sheet, each having a size 244 x 70 x 1.6 mm and are welded by a Laser CO 2 process. The welding parameters in the Laser CO 2 process are given in ...

The TRIP 800 steel examined here is a 1.6-mm-thick commercial sheet product obtained from a European steel company, with its chemical composition shown in Table I.In order to conduct the finite element analysis with the RVE based on an actual microstructure of the TRIP steel, the mechanical properties of ferrite, austenite, and bainite were first obtained based on the synchrotron-based in-situ ...

The intercritical annealing and isothermal bainitic processing response was studied for three Nb and V microalloyed Transformation-Induced Plasticity (TRIP)-assisted 980 MPa grade steels. Their mechanical and microstructural properties were compared to industrially produced TRIP 800 steel. Depending on the isothermal holding temperature and ...

This paper aims at investigating the fracture resistance of TRIP steels. For this purpose, a micromechanical finite element model is developed based on the actual microstructure of a TRIP 800 steel. Uniaxial tensile tests on TRIP 800 sheet notched specimens were also conducted and tensile properties and R-curves (Resistance curves) were determined.

In this study, a TRIP-800 steel was welded using a Laser CO2 process, and the resultant microstructures were characterized by optical, scanning, and transmission electron microscopy (TEM) means. It was found that the microstructure of the steel in the as-received condition consisted of ferrite, bainite, and retained austenite (RA), including some martensite. In particular, TEM observations ...

TRIP steels, or Transformed Induced Plasticity steels, have excellent mechanical properties if compared with conventional steels. Strain hardening is also great ... Springback evaluation for TRIP 800 steel sheets by simple bending tests F. J. Avellaneda; F. J. Avellaneda Regional Development Institute, Material Science and Engineering ...

Metallographic Analysis of a TRIP 800 Steel Using Digital Image Processing. In the second half of the last century, the automobile industries were affected from the petroleum crisis caused mainly by the wars in the Middle East. These crises led the automakers reconsider their vehicles.

Table 1 and Table 2 presents the fitted hardening parameters, elastic and thermal properties for TRIP 800 steel (Serri, 2006, Serri and Cherkaoui, 2008).Generic thermal and elastic properties of steel were assumed to be representative of TRIP 800. Table 1 also includes the ratio between the ultimate tensile strength and the yield stress of each phase (37) U i = σ u, i σ 0, i

UA effect on the plastic deformation of TRIP 800 steel by ultrasonically assisted micro-tensile testing. The testing stage developed in previous work[28] is also equipped with in situ digital image correlation (DIC) capability to analyze the evolution of strain distribution during deformation. Scanning electron microscopy

OPEN ACCESS ARTICLE TRIP 800 steel and DP 1000 steel welded by using the electron beam welding (EBW) method were investigated in this study. Martensite was a dominant phase at the fusion zone (FZ ...

In this paper, we study the crack propagation behavior and fracture resistance of a TRIP 800 steel using a microstructure-based finite element method with the various phase properties characterized by in-situ high energy Xray diffraction (HEXRD) technique. Uniaxial tensile tests on the notched TRIP 800 sheet specimens were also conducted, and ...

The mechanical properties of the constituent phases of the TRIP 800 steel and the fitting parameters describing the martensite transformation kinetics are determined using the synchrotron-based in-situ high-energy X-ray diffraction (HEXRD) experiments performed under a uniaxial tensile deformation. The experimental results suggest that the ...

An actual microstructure of a TRIP 800 steel is used to generate the representative volume element for the analyses. No prescribed failure criteria are used for the various constituent phases, and the initial microstructure inhomogeneity among the various phases serves as the imperfection condition triggering the plastic instability. The ...

With the support of our professional customer care team, we will develop a custom solution for your needs, specification and budget. Call 901-877-6875or Contact Us today to learn more about The Troxel Company. Phone 901-877-6875• Fax 901-877-3439. 11495 Hwy. 57 • P.O. Box 276.

Round table 2021. "Electrostal" Metallurgical plant" JSC has a number of remarkable time-tested traditions. One of them is holding an annual meeting with customers and partners in an extеnded format in order to build development pathways together, resolve pressing tasks and better understand each other. Although the digital age ...

Mill Length & Fabricated Aluminized Steel Tubing — The Troxel Company. Call 901-877-6875 or Contact Us today to learn more about The Troxel Company. Phone 901-877-6875 • Fax 901-877-3439. 11495 Hwy. 57 • P.O. Box 276. Moscow, TN 38057-0276. Troxel manufactures ASTM A787 aluminized tubing & fabricated tubular components with the lowest ...

We will continue to have controversy at the pinnacle of horse racing, as the favorite Muth comfortably took home the 2024 Arkansas Derby on Saturday from Oaklawn Park in Hot Springs, Arkansas.. Muth is trained by Bob Baffert, and his horses are ineligible to run in Kentucky due to a three-year suspension of the most decorated and controversial trainer of this era, the 100 points on on the Road ...

We very much enjoyed our group trip to Moscow and St Petersburg last year. excellent guides and accommodations. While Steven who has replied here has excellent advice, ( and we took advantage of it), we felt an organized tour really facilitated our enjoyment of the country. You may want to consider a combination of an organized tour and than ...